SUP-EC8.0 conductivity meter

-

Specification

| Product | Industrial conductivity meter |

| Model | SUP-EC8.0 |

| Measure range | 0.00uS/cm~2000mS/cm |

| Accuracy | ±1%FS |

| Measuring medium | Liquid |

| Input Resistance | ≥1012Ω |

| Temp compensation | Manual/ Auto temperaturecompensation |

| Temperature Range | -10-130℃, NTC30K or PT1000 |

| Temperature resolution | 0.1℃ |

| Temperature accuracy | ±0.2℃ |

| Communication | RS485, Modbus-RTU |

| Signal output | 4-20mA, maximum loop 500Ω |

| Power supply | 90 to 260 VAC |

| Weight | 0.85Kg |

-

Introduction

SUP-EC8.0 Industrial conductivity meter is widely applied for continuous monitoring and measurement of EC value or TDS value or EC value and temperature in the solution in the industry of thermal power, chemical fertilizer, environmental protection, metallurgy, pharmacy, biochemistry, food and water, etc.

-

Application

-

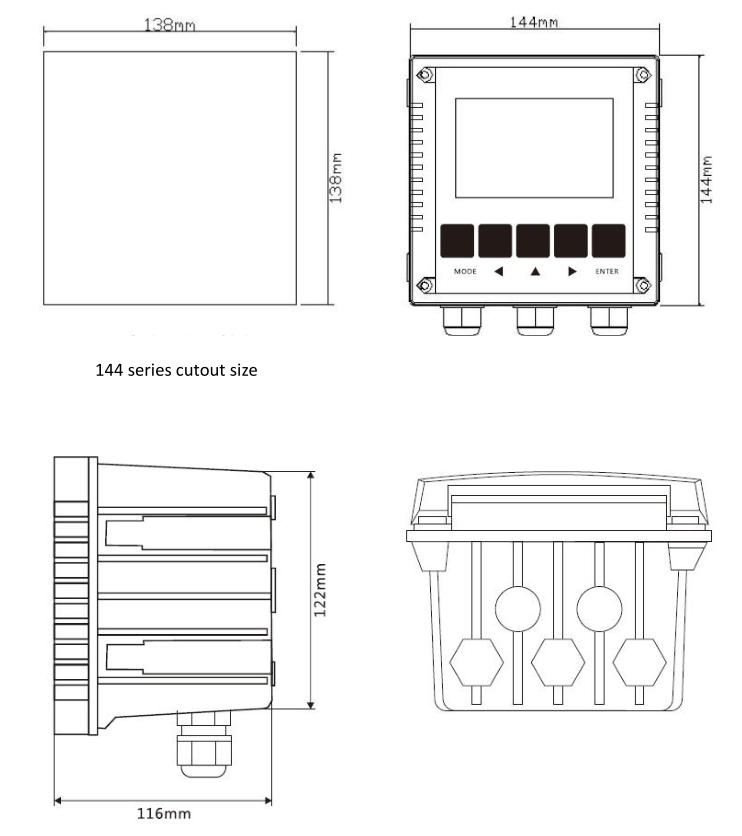

Dimension

Industrial controlled door keep, to avoid instrument halted.