PH163S pH Controller, ORP Controller for Industry/Laboratory Liquids Treatment

Introduction

Leveraging extensive experience in process instrumentation, the PH163S pH control and monitor facility provides a cost-effective solution for environments requiring robust data transmission and minimal downtime.

This pH control and ORP monitor instrument accommodates a wide array of electrodes, enabling flexible configurations for either pH or ORP modes without extensive rewiring. The unit’s high-impedance input ensures accurate capture of subtle electrochemical signals, while built-in compensation mechanisms adjust for environmental factors to deliver reliable outputs.

With a lightweight design and simple panel installation, it supports remote oversight via digital protocols, alarm activation for threshold breaches, and current loops for analog integration, all while operating efficiently within standard industrial power supplies.

Working Principle

Step 1: Signal Detection and Amplification

The controller captures electrochemical voltages from immersed electrodes, identifying differences caused by hydrogen ions in pH mode or redox reactions in ORP mode via a glass measuring electrode and a stable reference, then amplifies these signals through a high-resistance circuit to maintain accuracy without distortion.

Step 2: Digital Processing and Compensation

Amplified inputs undergo digital conversion with Nernst-based algorithms to compute precise values, incorporating temperature data from built-in sensors to automatically adjust for thermal influences on electrode behavior and ensure reliable calibration.

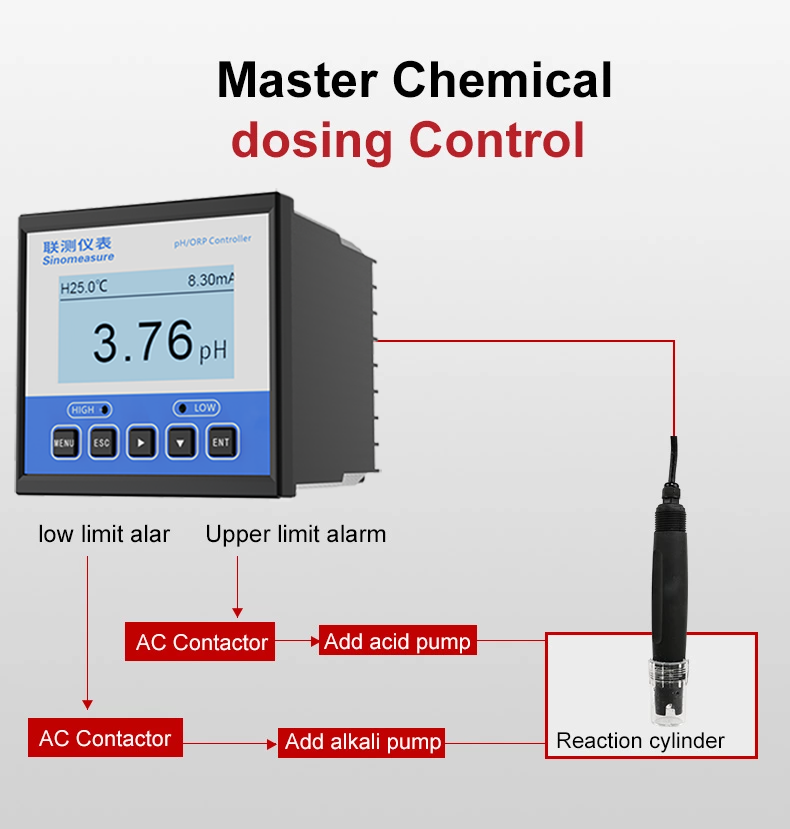

Step 3: Output and Control Activation

Final processed data is scaled to update the display, generate analog currents, enable digital transmission, and trigger relays for alarms or automation when predefined thresholds are met.

Key Features

Engineered for durability and ease of use, the PH163S pH/ORP controller incorporates advanced elements to support demanding monitoring tasks:

- Clear Display — 2.8-inch monochrome LCD (128×64 dots) with adjustable backlight for easy viewing of readings, trends, and diagnostics in any light.

- Isolated Outputs — Optical isolation for 4-20mA (up to 750 Ω) and RS485 Modbus-RTU to minimize noise and support secure, long-range connections to SCADA or PLCs.

- Dual Alarms — Independent high/low relays (AC250V/3A) with custom logic, delays, and buzzer for quick alerts.

- Easy Calibration — 2- or 3-point adjustments with standard buffers, ±2 pH or ±300 mV offsets, and storage of the last two calibrations.

- Smoothing and Hold — Adjustable damping (0–9 seconds) for steady readings; hold mode locks outputs during maintenance to avoid false triggers.

- Secure Interface — Password protection (default 0000, changeable) with a simple button menu for fast setup and checks.

- Wide Compatibility — Supports NTC10K or PT1000 temperature sensors; built-in excitation for direct probe connections.

Specification

| Product | pH meter, pH controller |

| Model | PH163S |

| Measure range | pH: 0-14 pH, ±0.02pH |

| ORP: -1000 ~1000mV, ±1mV | |

| Measuring medium | Liquid |

| Input Resistance | ≥1012Ω |

| Temp compensation | Manual/ Auto temperature compensation |

| Temperature Range | -10~130℃, NTC10K or PT1000 |

| Communication | RS485, Modbus-RTU |

| Signal output | 4-20mA, maximum loop 750Ω, 0.2%FS |

| Power supply | 220V±10%,50Hz110V±10%,50HzDC 24V, |

| Relay output | 250V, 3A |

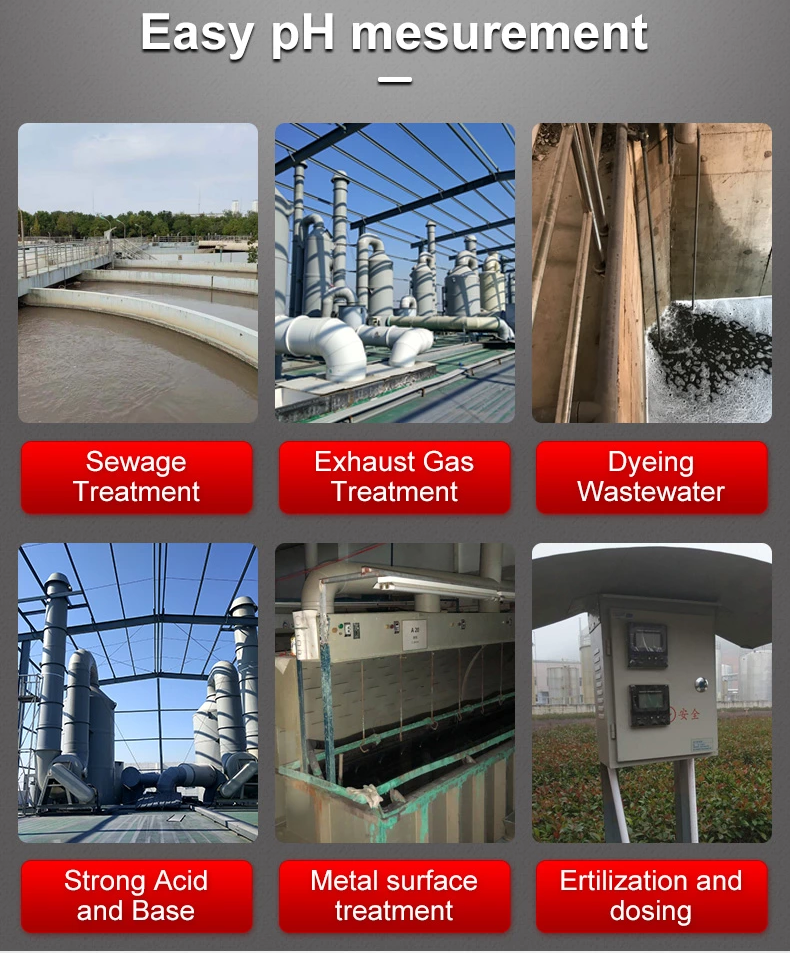

Applications

The PH163S pH ORP Controller is deployed across sectors where solution chemistry directly influences efficiency, safety, and compliance:

- Thermal Power and Metallurgy — Monitors boiler feedwater and corrosive streams to prevent scaling and equipment degradation.

- Chemical and Fertilizer Production — Regulates dosing in reaction vessels and neutralizes effluents for consistent yields.

- Environmental and Water Treatment — Oversees disinfection, flocculation, and pH balancing in sewage, pure water, and potable supplies.

- Pharmaceutical and Biochemical Processes — Controls fermentation baths and purification steps to maintain sterility and product integrity.

- Food Industry — Tracks acidity in processing lines for preservation and quality assurance.