PH6.3 pH Controller, ORP Controller for Industrial/Laboratory pH Control and Measuring

Introduction

This intelligent pH/ORP analyzer stands out as a refined solution, drawing on two decades of expertise to deliver seamless integration into industrial settings. Its switchable functionality allows instant toggling between pH and ORP modes without hardware changes, accommodating both combination electrodes and split configurations for flexible sensor pairing.

Its built-in sensor excitation supply simplifies connections, while the setup program enables intuitive configuration of alarms, outputs, and calibration routines. With low power consumption (≥6W) and robust signal transmission for remote SCADA or PLC systems, the PH6.0 pH controller/ORP controller ensures uninterrupted data logging and process optimization, reducing operational risks in variable-temperature applications.

Working principles

Step 1: Signal Acquisition and Amplification

The meter captures millivolt signals from connected electrodes, amplifying them via a high-impedance circuit to maintain integrity without distortion.

Step 2: Mode-Based Processing and Compensation

Depending on the selected mode, it applies Nernst-based calculations for pH (comparing glass and reference potentials) or direct redox interpretation for ORP, then incorporates automatic or manual temperature adjustments using integrated sensors to correct for thermal impacts on readings.

Step 3: Data Output and Control

Processed values are scaled for display on the LCD, transmitted through analog current loops or digital protocols, and used to activate relays for automated responses based on user-defined setpoints.

Key features

This controller combines simplicity and advanced control elements tailored for seamless deployment:

- Dual-Mode Versatility: Effortless on-device switching between pH and ORP without reconfiguration.

- Versatile Temperature Options: Supports NTC10K for -10°C to 130°C (±0.3°C up to 60°C, ±2°C beyond) or PT1000 for full-range precision.

- Enhanced Communication: Isolated RS-485 interface enables MODBUS-RTU data exchange, including register access for pH, ORP, and temperature.

- Alarm Customization: Two independent channels with normally open/closed contacts, adjustable delays, and a linked buzzer for immediate notifications.

- Calibration Flexibility: Online adjustments with pH/ORP modifications (±2 pH or ±300 mV) and temperature offsets (±20°C) to fine-tune accuracy.

- Protective Design: Password access (default 0000, modifiable) prevents unauthorized changes, paired with overload safeguards.

- Efficient Interface: Button-driven menu system (ESC, RIGHT, MENU, DOWN, ENTER) for quick parameter setup and diagnostics.

Specification

| Product | pH meter, pH controller |

| Model | SUP-PH6.3 |

| Measure range | pH: 0-14 pH, ±0.02pH |

| ORP: -1000 ~1000mV, ±1mV | |

| Measuring medium | Liquid |

| Input Resistance | ≥1012Ω |

| Temp compensation | Manual/ Auto temperature compensation |

| Temperature Range | -10~130℃, NTC10K or PT1000 |

| Communication | RS485, Modbus-RTU |

| Signal output | 4-20mA, maximum loop 750Ω, 0.2%FS |

| Power supply | 220V±10%,24V±20%,50Hz/60Hz |

| Relay output | 250V, 3A |

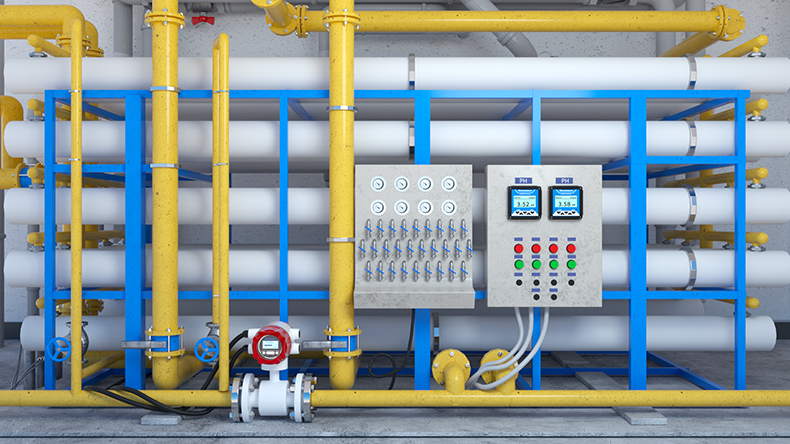

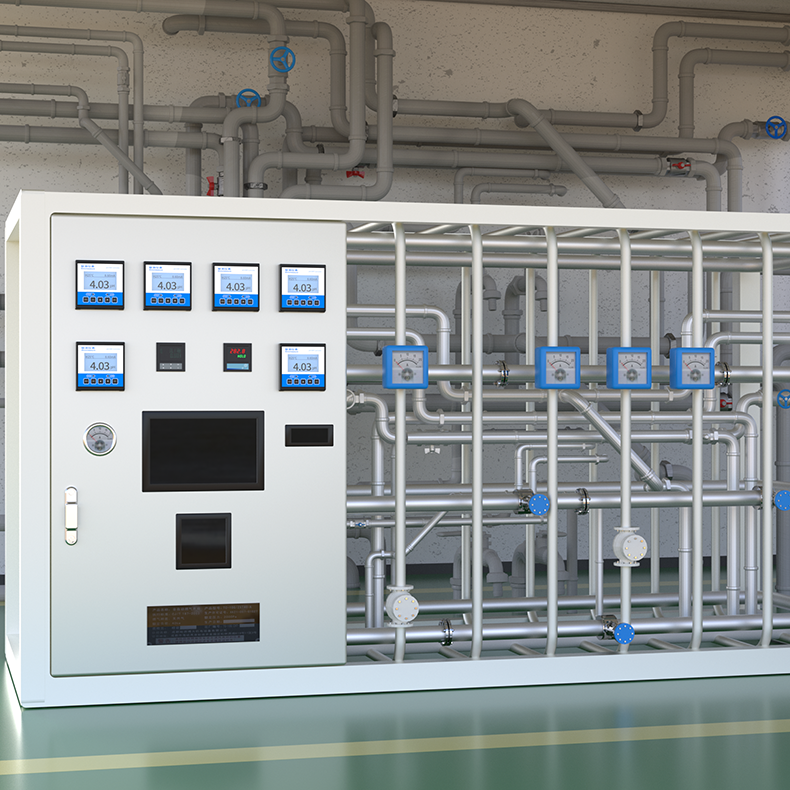

Applications

The PH6.0 pH value monitoring and measuring tool suits a range of sectors where solution monitoring ensures operational safety and quality:

- Thermal power and metallurgy — Manages boiler feedwater and corrosion in high-heat circuits.

- Chemical fertilizer and pharmaceuticals — Oversees reactant dosing and biochemical reactions.

- Environmental protection and tap water — Facilitates effluent neutralization and disinfection.

- Food processing and biochemistry — Controls fermentation and preservation conditions