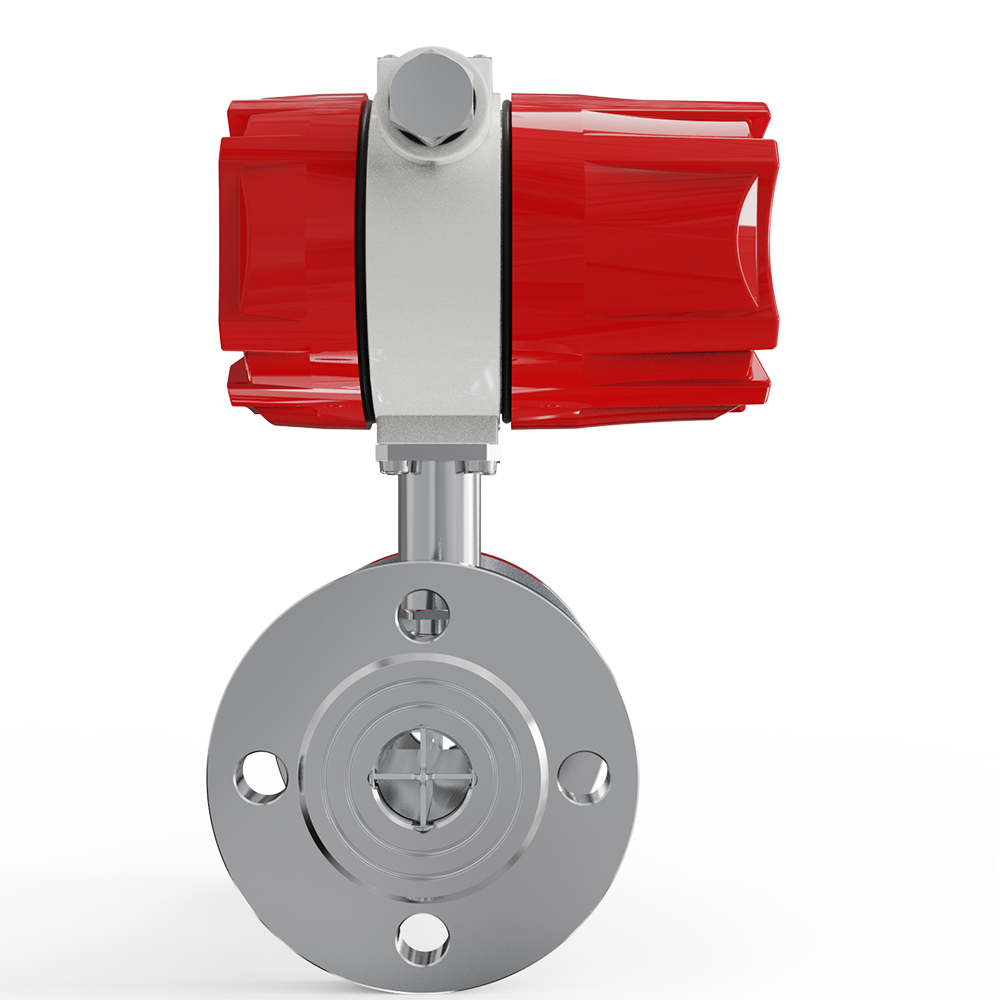

SUP-LWGY Turbine Flow Meter Flange Connection High Accuracy Measuring

Introduction

The LWGY-SUP Turbine Flow Meter is a velocity-based flow measurement device known for its high accuracy, excellent repeatability, simple design, minimal pressure loss, and ease of maintenance. It is specifically designed to measure the volumetric flow rate of low-viscosity liquids in closed pipelines.

Working Principle

The LWGY-SUP Turbine Flow Meter operates on the principle of fluid dynamics, where the flow of liquid causes a turbine rotor to spin. Inside the meter, a freely rotating turbine is positioned in the path of the fluid flow. As the low-viscosity liquid passes through the pipeline, it impinges on the turbine blades, causing the rotor to rotate at a speed proportional to the fluid velocity. The rotation of the turbine is detected by a sensor (typically magnetic or optical), which generates electrical pulses corresponding to the rotor’s revolutions. These pulses are then processed by the meter’s electronics to calculate the volumetric flow rate, as the frequency of the pulses is directly proportional to the flow velocity and, consequently, the volume of liquid passing through the meter. This design ensures precise and reliable measurement with minimal interference to the flow.

Specification

| Products | Turbine flow meter |

| Model no. | LWGY-SUP |

| Diameter | DN4~DN200 |

| Pressure | 1.0MPa~6.3MPa |

| Accuracy | 0.5%R(standard), 1.0%R |

| Medium viscosity | Less than 5×10-6m2/s (for the liquid with >5×10-6m2/s, |

| The flowermeter needs to be calibrated before using. | |

| Temperature | -20 to 120℃ |

| Power Supply | 3.6V lithium battery; 12VDC; 24VDC |

| Output | Pulse, 4-20mA, RS485 Modbus |

| Ingress protection | IP65 |

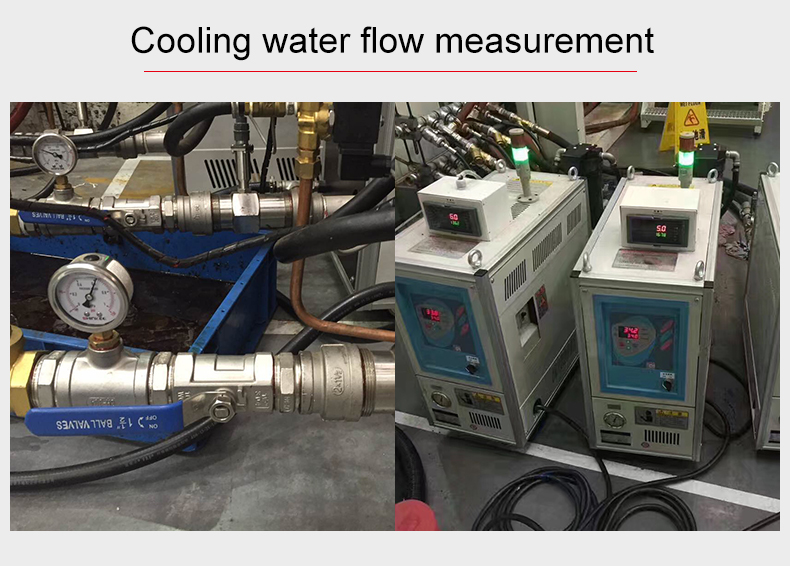

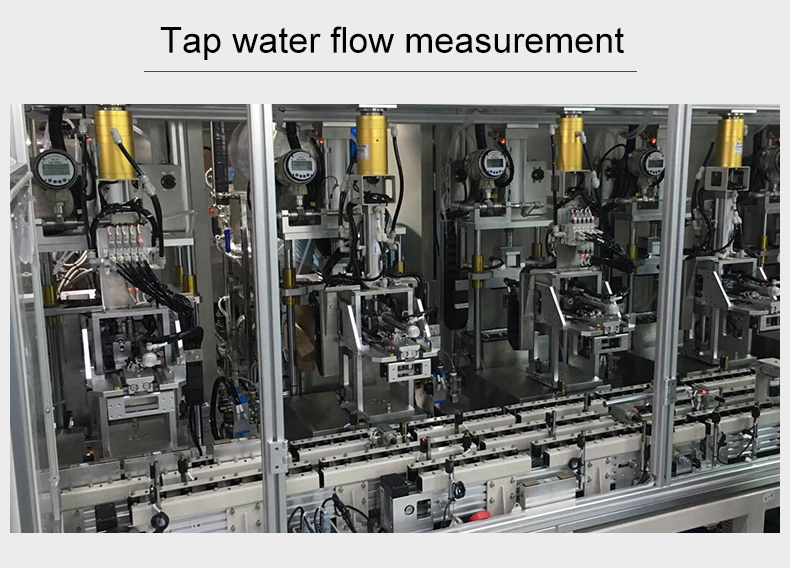

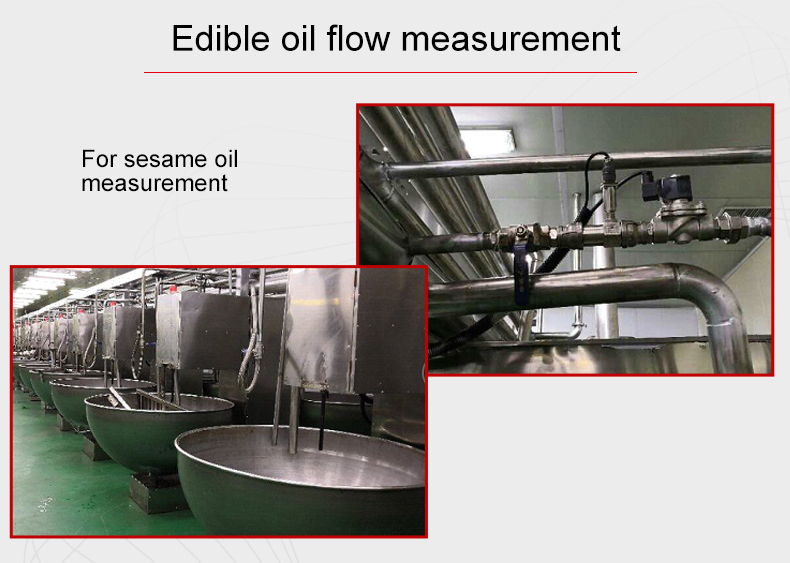

Application