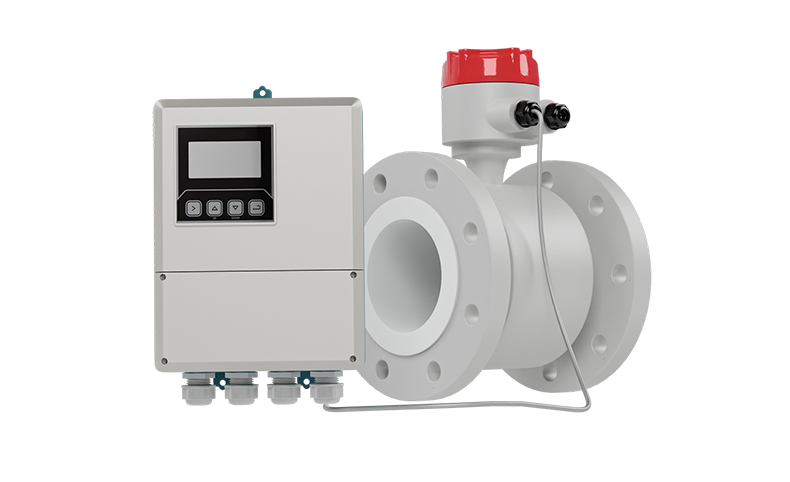

LDGR Electromagnetic BTU Meter, Electromagnetic Flow Meter for Industrial Liquids Measuring

Introduction

The LDGR Electromagnetic BTU Meter is engineered for precise measurement of thermal energy in fluid systems. Utilizing electromagnetic flow sensing and integrated BTU calculation, it offers enhanced accuracy and durability in demanding environments. Whether in district heating systems, industrial process monitoring, or heating/cooling systems, this meter provides consistent and reliable energy usage data, ensuring optimal performance and efficiency.

This flow meter is built to withstand the rigors of both industrial and commercial settings, with a robust design that supports continuous operation in high-pressure and high-temperature environments. With its versatile communication options and ease of integration into existing energy management systems, it stands as an essential tool for accurate thermal measurement.

Working principle

The LDGR Electromagnetic BTU Meter operates on the principle of electromagnetic flow measurement. It utilizes Faraday’s Law of Induction, which states that when a conductive fluid flows through a magnetic field, a voltage is induced proportional to the flow rate. This is measured by the sensor electrodes.

The meter integrates this flow measurement with temperature sensors to calculate thermal energy (BTU). By simultaneously monitoring the temperature difference between the incoming and outgoing fluid, the meter uses the formula:

BTU=Flow Rate×Temperature Difference×Specific Heat Capacity

This ensures precise energy consumption data, which is crucial for evaluating energy efficiency and optimizing usage in heating, cooling, and industrial processes.

Key features

The LDGR Electromagnetic BTU Meter delivers precise thermal energy measurements through advanced flow sensing and BTU calculation, ensuring reliable performance in diverse applications.

-

Electromagnetic flow measurement: Offers non-invasive and precise flow measurement, unaffected by changes in fluid viscosity or density.

-

Accurate thermal energy calculation: Integrated sensors measure both flow rate and temperature differential for precise BTU calculation.

-

High-performance in harsh conditions: Designed to operate in high-pressure and high-temperature environments, ensuring reliable performance in demanding applications.

-

Durable and long-lasting: Built with high-quality materials to ensure long-term reliability and resistance to wear and tear.

-

Wide measurement range: Supports a wide range of pipe sizes and fluid types, making it adaptable for diverse industrial applications.

-

Flexible communication options: Offers various communication protocols (Modbus, M-Bus, etc.) for easy integration into building management systems and energy monitoring platforms.

-

User-friendly interface: Equipped with an intuitive display for easy setup, operation, and real-time monitoring of energy data.

-

Low maintenance: The design minimizes the need for maintenance and is resistant to clogging or buildup, reducing operational downtime.

Specification

| Product | Electromagnetic BTU meter |

| Model | SUP-LDGR |

| Diameter nominal | DN15 ~DN1000 |

| Accuracy | ±2.5%,(flowrate=1m/s) |

| Working pressure | 1.6MPa |

| Liner material | PFA, F46, Neoprene, PTFE, FEP |

| Electrode material | Stainless steel SUS316, Hastelloy C, Titanium, |

| Tantalum, Platinum-iridium | |

| Medium temperature | Integral type: -10℃~80℃ |

| Split type: -25℃~180℃ | |

| Power supply | 100-240VAC,50/60Hz, 22VDC—26VDC |

| Electrical conductivity | > 50μS/cm |

| Ingress protection | IP65, IP68 |

Applications

The LDGR Electromagnetic BTU Meter is ideal for a range of applications where accurate energy measurement is essential:

-

District heating systems: Accurately measure energy consumption in centralized heating systems, providing data for efficient operation and energy distribution.

-

HVAC systems: Monitors energy usage in heating, ventilation, and air conditioning systems, optimizing energy efficiency and performance.

-

Water heating systems: Ensures precise energy monitoring for water heating applications, from residential units to industrial-scale boilers.

-

Industrial process monitoring: Used in manufacturing and process industries to monitor energy usage, ensuring that heating or cooling processes are operating within desired parameters.

-

Building energy management: Helps in managing energy consumption in commercial buildings, assisting with billing, maintenance, and overall energy optimization.

-

Renewable energy systems: Ideal for monitoring energy generation in systems like geothermal or solar thermal, ensuring optimal energy extraction and usage.