LDG-C Electromagnetic Flow Meter, Electromagnetic Flow Meter Manufacturers for Liquids Measuring

Introduction

The LDG-C Electromagnetic Flow Meter utilizes the principle of Faraday’s Law of Induction to accurately measure the flow rate of conductive liquids. As the liquid passes through a magnetic field, voltage is induced, which is then used to determine flow. This non-intrusive, low-maintenance flow meter offers exceptional precision in applications such as water management, chemical production, and food processing.

With no moving parts, the LDG-C Electromagnetic Flow Meter is highly durable and resistant to wear and tear. The meter can handle a wide range of pipe sizes and flow conditions, providing accurate measurements even under high pressures and temperatures. It also supports a variety of communication protocols, making it easy to integrate into existing monitoring and control systems.

Key Features

-

Electromagnetic flow sensing: Utilizes Faraday’s Law of Induction to ensure highly accurate flow measurement.

-

No moving parts: No moving parts reduces wear and maintenance requirements, leading to longer-lasting operation.

-

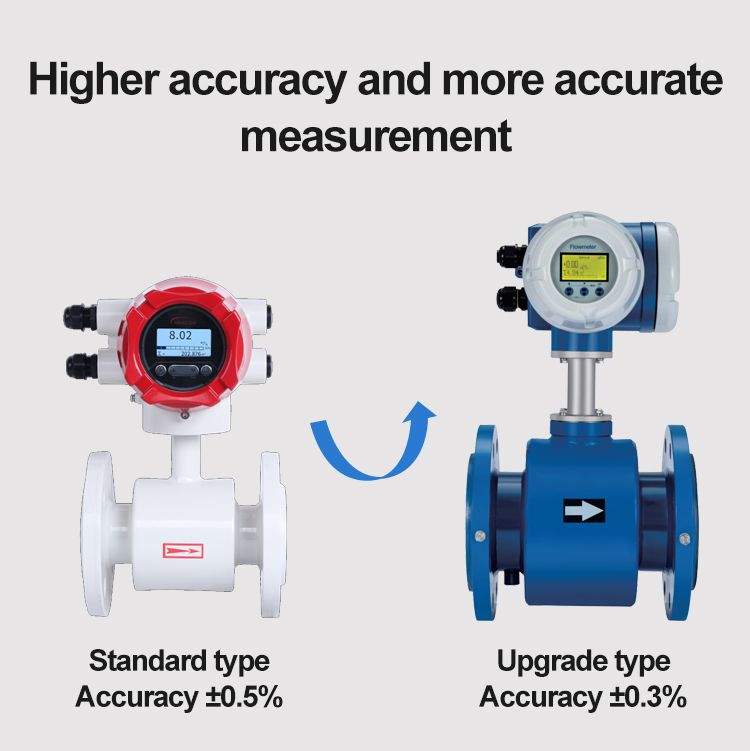

High accuracy: Provides precise flow measurements even at varying flow rates, pressures, and temperatures.

-

Wide measurement range: Capable of measuring a wide range of pipe sizes and flow conditions.

-

Durability: Built to withstand harsh environments, including high pressures and extreme temperatures, ensuring long-term reliability.

-

Versatile communication: Supports multiple communication protocols like Modbus, M-Bus, and analog outputs for easy integration into control systems.

-

User-friendly interface: Simple to install and operate with clear readings and easy calibration.

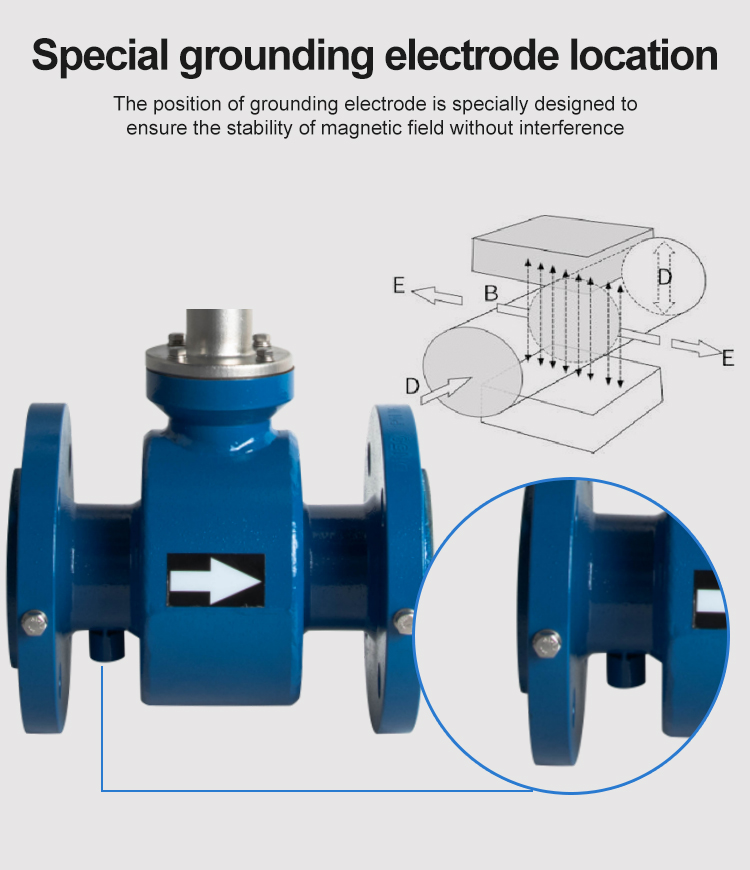

Measuring principle

The mag meter works based on Faraday’s law. When the liquid goes through the pipe at the flow rate of v with a diameter D, within which a magnetic flux density of B is created by an exciting coil, the following electromotive force E is generated in proportion to the flow speed v:

E=K×B×V×D

Where:

- E-Induced electromotive force

- K-Meter constant

- B-Magnetic induction density

- V-Average flow speed in cross-section of measuring tube

- D-Inner diameter of measuring tube

Applications

The LDG-C Electromagnetic Flow Meter is versatile and can be applied across a variety of industries:

-

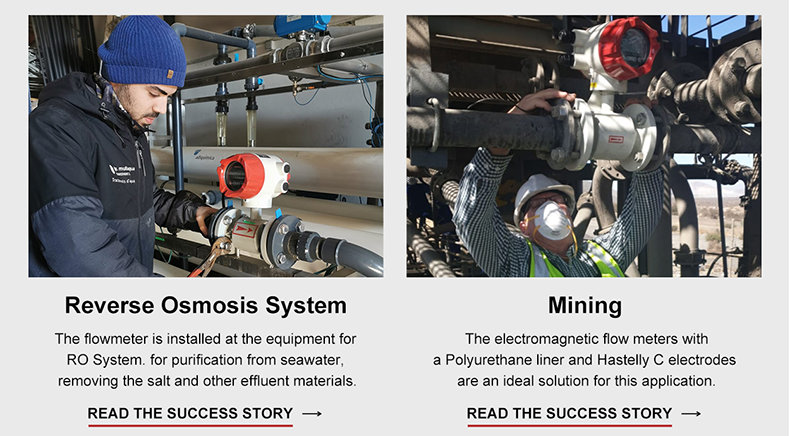

Water treatment: Ideal for measuring water flow in treatment plants, ensuring proper system operation, and optimal water quality.

-

Chemical processing: Accurately measures the flow of chemicals in manufacturing processes, providing real-time data for efficient production.

-

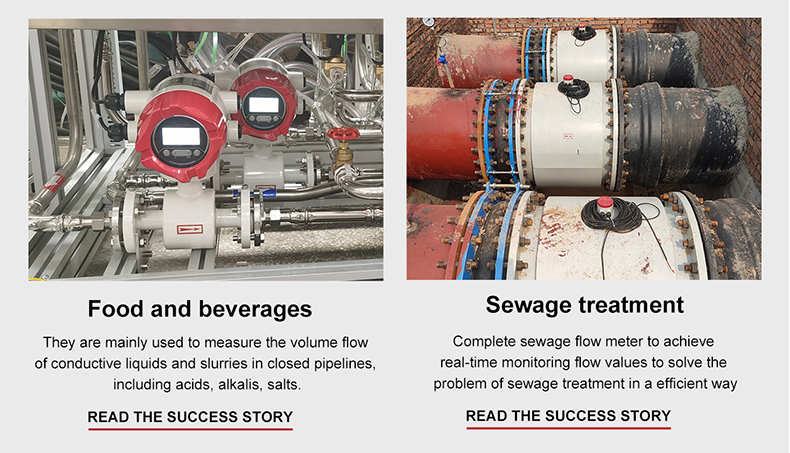

Food and beverage: Monitors liquid flow in food and beverage production lines, helping to maintain product consistency and quality.

-

Pulp and paper: Used in pulp and paper mills to measure the flow of water and chemicals in various stages of production.

-

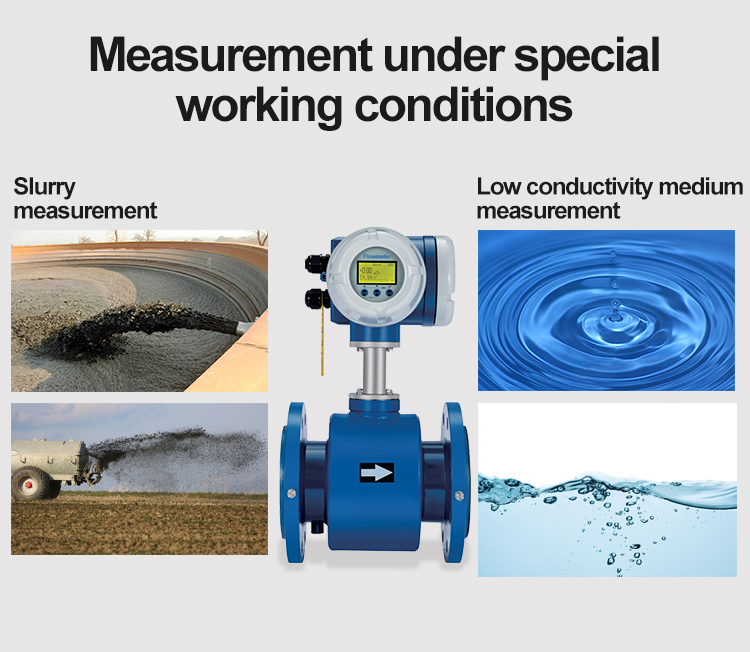

Mining and metallurgy: Ensures accurate flow measurements in mining operations, especially for slurry and other conductive liquids.

-

Energy and power: Used in power plants to measure flow in cooling systems and other processes requiring reliable liquid flow data.

-

HVAC systems: Measure flow in heating, ventilation, and air conditioning systems for better energy management and performance.

Specification

| Product | Electromagnetic flow meter |

| Model | LDG-C |

| Diameter nominal | DN15~DN1000 |

| Nominal pressure | DN6 – DN80, PN<4.0MPa; DN100 – DN150, PN<1.6MPa; DN200 – DN1000, PN<1.0MPa; DN1200 – DN2000, PN<0.6MPa |

| Accuracy | ±0.3%,±2mm/s(flowrate<1m/s) |

| Repetitiveness | 0.15% |

| Liner material | PFA, F46, Neoprene, PTFE, FEP |

| Electrode material | Stainless steel SUS316, Hastelloy C, Titanium, Tantalum, Platinum-iridium |

| Medium temperature | Integral type: -10℃~80℃; Split type: -25℃~180℃ |

| Power supply | 100-240VAC,50/60Hz / 22VDC—26VDC |

| Electrical conductivity | IP65, IP68(optional) |

| Product standard | JB/T 9248-2015 |

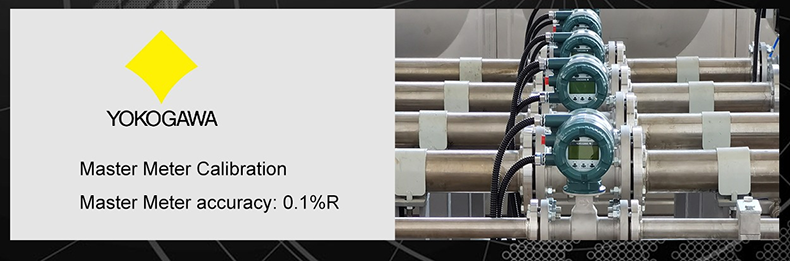

Automatic calibration line