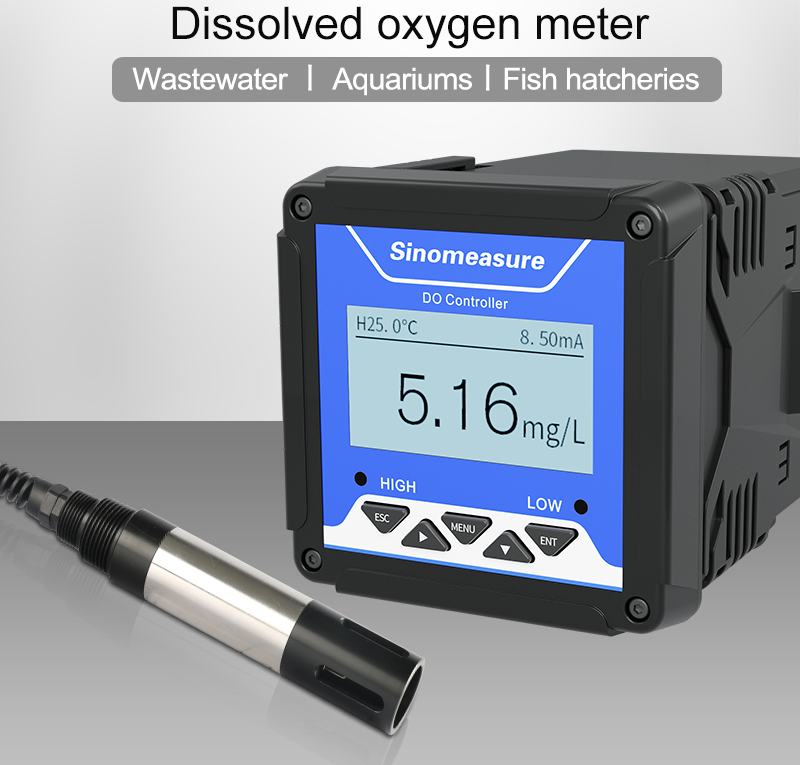

DO7011 Dissolved Oxygen Sensor Membrane Type for Industrial/Environmental Water Measuring

Introduction

The DO7011 sensor measures the concentration of oxygen dissolved in liquids using a membrane-based polarographic method. In this principle, oxygen diffuses through a semipermeable membrane into an electrolyte chamber where it undergoes an electrochemical reduction reaction.

The resulting current is proportional to the dissolved oxygen concentration. The sensor provides a 4–20 mA output that can be read by dissolved oxygen transmitters, dissolved oxygen controllers, or core data acquisition systems. Its design accommodates a range of working conditions, with a measurement range up to 20 mg/L, integrated temperature compensation using standard temperature elements (e.g., Pt100, Pt1000), and robust materials for stable, prolonged deployment.

Working theory

The working theory of the DO7011 can be summarized in four core stages:

1. Oxygen Diffusion through Membrane

Dissolved oxygen molecules in the liquid diffuse through the sensor’s membrane, which separates the process fluid from the internal electrolyte.

2. Electrochemical Reaction

Once inside, oxygen undergoes a reduction reaction at the cathode of the polarographic electrode, generating a small electric current. The magnitude of this current is directly related to the amount of dissolved oxygen.

3. Temperature Compensation

Because dissolved oxygen readings can be affected by temperature, the SUP-DO7011 incorporates temperature sensing (e.g., Pt100 or Pt1000). This allows accurate compensation and consistent measurements across varying thermal conditions.

4. Signal Output

The sensor converts the measured electrochemical current into a 4–20 mA analog output, representing the dissolved oxygen value. This output can be integrated into control systems or monitoring platforms for real-time data use.

Key features

The SUP-DO7011 Membrane Dissolved Oxygen Sensor is engineered for reliable, long-term online use. Its key features include:

-

Membrane Polarographic Measurement: Detects dissolved oxygen using a well-established polarographic principle, providing stable and repeatable results.

-

Wide Measurement Range: Capable of measuring dissolved oxygen levels up to 20 mg/L, suitable for most industrial and environmental applications.

-

Temperature Compensation: An integrated temperature element (e.g., Pt100, Pt1000, or others) ensures accurate DO readings across varying water temperatures.

-

Standard 4–20 mA Output: The analog current output enables seamless integration with transmitters, PLCs, and SCADA systems.

-

Robust Construction: Sensor body built with materials such as PVC or 316L stainless steel for reliable performance in demanding field conditions.

-

Extended Cable Options: Standard shielded cable ensures reliable signal transmission; length can be configured for specific installations.

Specification

| Product | Dissolved oxygen sensor |

| Model | DO7011 |

| Measure range | DO:0-20 mg/L、0-20 ppm;Temperature:0-45℃ |

| Accuracy | DO:±3% of the measured value; Temperature:±0.5℃ |

| Temperature Type | NTC 10k/PT1000 |

| Output Type | 4-20mA output |

| Weight | 1.85Kg |

| Cable length | Standard:10m, the maximum may be extended to 100m |

Applications

The DO7011 dissolved oxygen measuring sensor is suitable for continuous dissolved oxygen monitoring in a variety of industrial and environmental settings, including:

-

Wastewater Treatment: Tracking dissolved oxygen in aeration basins and effluent streams to optimize biological treatment processes and ensure regulatory compliance.

-

Environmental Monitoring: Measuring oxygen levels in rivers, lakes, and reservoirs to assess ecological health and water quality.

-

Aquaculture: Ensuring dissolved oxygen is maintained within healthy ranges for fish and aquatic organisms in ponds, tanks, and culture systems.

-

Industrial Water Systems: Monitoring oxygen concentration in cooling water and process lines to support corrosion control and process quality.

-

General Water Quality Analysis: Used in waterworks, surface water assessments, and industrial production processes where DO data support operational decisions.