Flow rate is a commonly used process control parameter in industrial production processes. Currently, there are approximately more than 100 different flow meters on the market. How should users choose products with higher performance and price? Today, we will take everyone to understand the performance characteristics of flow meters.

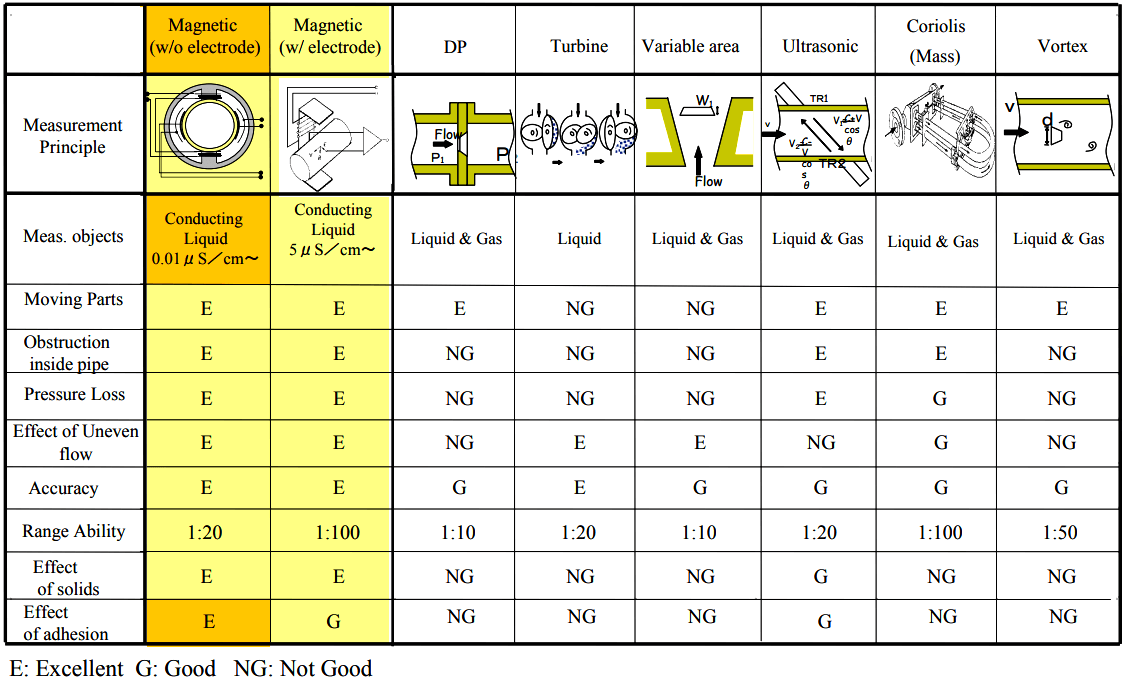

Comparison of Different Flow Meters

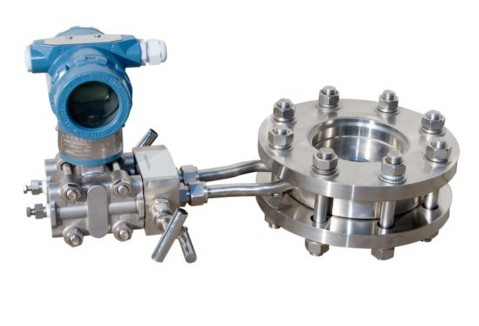

Differential pressure type

Differential pressure measurement technology is currently the most widely used flow measurement method, which can almost measure the flow of single-phase fluids and fluids under high temperature and high pressure under various working conditions. In the 1970s, this technology once accounted for 80% of the market share. The differential pressure flowmeter is generally composed of two parts, a throttling device and a transmitter. Throttle devices, common orifice plates, nozzles, pitot tubes, uniform velocity tubes, etc. The function of the throttling device is to shrink the flowing fluid and make a difference between its upstream and downstream. Among various throttling devices, the orifice plate is the most commonly used because of its simple structure and easy installation. However, it has strict requirements on processing dimensions. As long as it is processed and installed in accordance with the specifications and requirements, the flow measurement can be performed within the uncertainty range after the inspection is qualified, and the actual liquid verification is not required.

All throttling devices have an unrecoverable pressure loss. The largest pressure loss is the sharp-edged orifice, which is 25%-40% of the maximum difference of the instrument. The pressure loss of the Pitot tube is very small and can be ignored, but it is very sensitive to changes in the fluid profile.

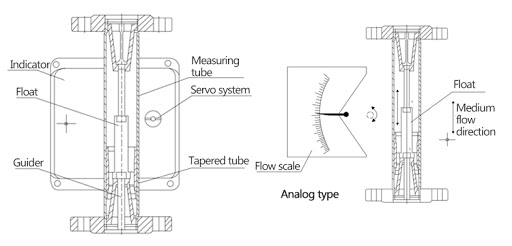

Variable area type

A typical representative of this type of flowmeter is a rotameter. Its outstanding advantage is that it is direct and does not require an external power supply when measuring on-site.

Rotameters are divided into glass rotameters and metal tube rotameters according to their manufacturing and materials. The glass rotor flowmeter has a simple structure, the rotor position is clearly visible, and it is easy to read. It is mostly used for normal temperature, normal pressure, transparent and corrosive media, such as air, gas, argon, etc. Metal tube rotameters are generally equipped with magnetic connection indicators, used in high temperature and high pressure situations, and can transmit standard signals to be used with recorders, etc., to measure cumulative flow.

At present, there is a vertical variable area flowmeter with a loaded spring conical head on the market. It does not have a condensing type and a buffer chamber. It has a measurement range of 100:1 and has a linear output, which is most suitable for steam measurement.

Oscillating

Vortex flowmeter is a typical representative of oscillating flow meters. It is to place a non-streamlined object in the forward direction of the fluid, and the fluid forms two regular asymmetric vortex rows behind the object. The frequency of the vortex train is proportional to the flow velocity.

The characteristics of this measurement method are no moving parts in the pipeline, repeatability of readings, good reliability, long service life, wide linear measurement range, almost unaffected by changes in temperature, pressure, density, viscosity, etc., and low pressure loss. High accuracy (about 0.5%-1%). Its working temperature can reach over 300℃, and its working pressure can reach over 30MPa. However, the fluid velocity distribution and pulsating flow will affect the measurement accuracy.

Different media can use different vortex sensing technologies. For steam, vibrating disc or piezoelectric crystal can be used. For air, thermal or ultrasonic can be used. For water, almost all sensing technologies are applicable. Like orifice plates, vortex The flow coefficient of the street flow meter is also determined by a set of dimensions.

Electromagnetic

This type of flowmeter uses the magnitude of the induced voltage generated when the conductive flow flows through the magnetic field to detect the flow. Therefore it is only suitable for conductive media. Theoretically, this method is not affected by the temperature, pressure, density and viscosity of the fluid, the range ratio can reach 100:1, the accuracy is about 0.5%, the applicable pipe diameter is from 2mm to 3m, and it is widely used in water and mud , Pulp or corrosive medium flow measurement.

Due to the weak signal, the electromagnetic flowmeter is usually only 2.5-8mV at full scale, and the flow rate is very small, only a few millivolts, which is susceptible to external interference. Therefore, it is required that the transmitter housing, shielded wire, measuring conduit, and pipes at both ends of the transmitter must be grounded and set a separate grounding point. Never connect to the public ground of motors, electrical appliances, etc.

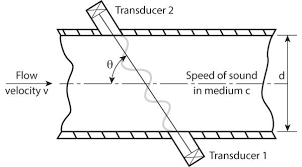

Ultrasonic type

The most common types of flow meters are Doppler flow meters and time difference flow meters. The Doppler flowmeter detects the flow rate based on the change in the frequency of the sound waves reflected by the moving target in the measured fluid. This method is suitable for measuring high-speed fluids. It is not suitable for measuring low-speed fluids, and the accuracy is low, and the smoothness of the inner wall of the pipe is required to be high, but its circuit is simple.

The time difference flowmeter measures the flow rate according to the time difference between the forward and backward propagation of ultrasonic waves in the injection fluid. Since the magnitude of the time difference is small, in order to ensure the measurement accuracy, the requirements for the electronic circuit are high, and the cost of the meter increases accordingly. The time difference flowmeter is generally suitable for pure laminar flow liquid with uniform flow velocity field. For turbulent liquids, multi-beam time difference flowmeters can be used.

Momentum rectangle

This type of flowmeter is based on the principle of conservation of moment of momentum. The fluid impacts the rotating part to make it rotate, and the speed of the rotating part is proportional to the flow rate. Then use methods such as magnetism, optics, and mechanical counting to convert the speed into an electrical signal to calculate the flow rate.

Turbine flowmeter is the most widely used and high-precision type of this type of instrument. It is suitable for gas and liquid media, but it is slightly different in structure. For gas, its impeller angle is small and the number of blades is large. , The accuracy of the turbine flowmeter can reach 0.2%-0.5%, and it can reach 0.1% in a narrow range, and the turndown ratio is 10:1. The pressure loss is small and the pressure resistance is high, but it has certain requirements on the cleanliness of the fluid, and is easily affected by the density and viscosity of the fluid. The smaller the hole diameter, the greater the impact. Like the orifice plate, ensure that there is enough before and after the installation point. Straight pipe section to avoid fluid rotation and change the angle of action on the blade.

Positive displacement

The working principle of this kind of instrument is measured according to the precise movement of a fixed amount of fluid every one revolution of the rotating body. The design of the instrument is different, such as oval gear flowmeter, rotary piston flowmeter, scraper flowmeter and so on. The range of the oval gear flowmeter is relatively large, which can reach 20:1, and the accuracy is high, but the moving gear is easy to be stuck by impurities in the fluid. The unit flow rate of the rotary piston flowmeter is large, but due to structural reasons, the leakage volume is relatively high. Large, poor accuracy. The positive displacement flowmeter is basically independent of fluid viscosity, and is suitable for media such as grease and water, but not suitable for media such as steam and air.

Each of the above-mentioned flowmeters has its own advantages and disadvantages, but even if it is the same type of meter, the products provided by different manufacturers have different structural performances.

Post time: Dec-15-2021