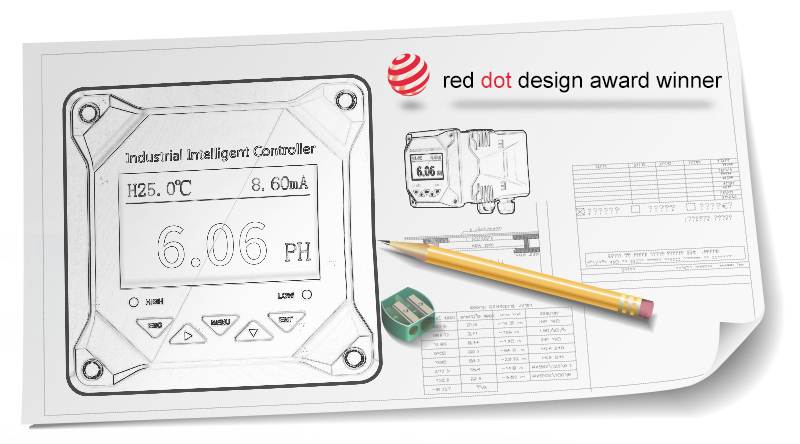

PH6.0 pH Controller, ORP Controller, Online Liquid Monitoring for Industry and Laboratory

Introduction

This intelligent online liquid analyzer stands out as a refined solution, leveraging two decades of expertise to deliver seamless integration into industrial settings. Its switchable functionality allows instant toggling between pH and ORP modes without hardware changes, accommodating both combination electrodes and split configurations for flexible sensor pairing.

The built-in pH sensor excitation supply simplifies connections, while the setup program enables intuitive configuration of alarms, outputs, and calibration routines. With low power consumption (≥6W) and robust signal transmission for remote SCADA or PLC systems, the PH6.0 pH control and monitor instrument ensures uninterrupted data logging and process optimization, reducing operational risks in variable-temperature applications.

Working principle

Step 1: The PH6.0 pH/ORP Controller processes signals from connected electrodes to compute real-time values.

For pH mode, it amplifies the millivolt potential from the glass membrane against a stable reference, applying temperature corrections to yield the final reading.

In ORP mode, it directly interprets the redox potential difference.

Step 2: Incoming data passes through high-impedance amplification (≥10¹² Ω) to preserve signal integrity, followed by digital conversion and compensation algorithms that adjust for thermal influences.

Step 3: Outputs are scaled linearly, e.g., 4-20 mA proportional to the measured range, triggering relays for setpoint-based control, all processed via embedded Modbus-RTU for networked oversight.

Key features

What elevates the pH6.0 ORP or pH controller for demanding working environments is its blend of simplicity and advanced control elements tailored for seamless deployment:

- Dual-Mode Versatility — Effortless on-device switching between pH and ORP without reconfiguration.

- Integrated Sensor Support — Built-in excitation for direct connection of glass or combination probes, streamlining wiring.

- High-Resolution Display — Backlit LCD for clear visibility of real-time pH/ORP/temperature trends and diagnostics.

- Flexible Output Suite — Isolated 4-20 mA for analog loops, RS-485 for digital networking, and dry relays for on/off automation.

- Precision Compensation — Auto/manual modes with NTC10K/PT1000 to handle process fluctuations up to 130°C.

- Programming Ease — Guided setup interface for custom alarms, calibration intervals, and output scaling.

- Compact Reliability — Low-power design with overload protection, ideal for field or panel mounting.

Specification

| Product | pH meter, pH controller |

| Model | PH6.0 |

| Measure range | pH: 0-14 pH, ±0.02pH |

| ORP: -1000 ~1000mV, ±1mV | |

| Measuring medium | Liquid |

| Input Resistance | ≥1012Ω |

| Temp compensation | Manual/ Auto temperature compensation |

| Temperature Range | -10~130℃, NTC10K or PT1000 |

| Communication | RS485, Modbus-RTU |

| Signal output | 4-20mA, maximum loop 750Ω, 0.2%FS |

| Power supply | 220V±10%,24V±20%,50Hz/60Hz |

| Relay output | 250V, 3A |

Application

Deploy the PH6.0 pH/ORP monitoring equipment wherever real-time pH/ORP oversight drives efficiency and compliance in fluid handling:

- Chemical and metallurgical operations — Regulate reactant dosing and corrosion prevention in aggressive solutions.

- Environmental protection systems — Track effluent quality in pollution control and remediation sites.

- Food and agricultural processing — Maintains optimal acidity for fermentation, irrigation, and product preservation.

- Water treatment facilities — Automate neutralization and disinfection in municipal or industrial purification.

- General manufacturing lines — Ensure consistent quality in plating baths, cleaners, and rinse cycles.