PH5019 Plastic pH Sensor Probe, pH Sensor Electrode, Water pH Sensor for Industry and Laboratory

Introduction

This economical water pH electrode integrates a sensitive glass membrane, gel electrolyte, and double-junction reference system into a rugged plastic body, eliminating fragile external glass components exposed to mechanical damage. The large-area PTFE diaphragm minimizes junction potential drift and resists clogging from particulates or precipitates.

With fast response times (<1 minute typical), excellent stability against strong acids/alkalis, and compatibility with most pH transmitters via BNC or direct cable output, the PH5019 digital pH sensor provides accurate, low-maintenance monitoring across a broad spectrum of process conditions. Its sealed construction and optional temperature compensation ensure consistent readings even in fluctuating environments, making it a versatile upgrade from laboratory-style probes for continuous industrial use.

How does the plastic pH sensor electrode work?

The PH5019 water pH sensor functions as a potentiometric sensor in pH value measurement. Firstly, the thin pH-sensitive glass membrane generates a voltage proportional to the hydrogen ion activity difference between the internal buffer (fixed pH) and the external process solution.

Then, the stable reference electrode, filled with KCl gel and connected via a porous PTFE salt bridge, provides a constant potential for comparison. This potential difference, typically 59.16 mV per pH unit at 25°C, is measured and converted by a transmitter into a pH value.

Finally, the built-in NTC10K thermistor automatically compensates for temperature effects on slope and zero point, ensuring accuracy across the operating range, and response with precision pH value readings.

Key features

The PH5019 industrial pH sensor stands out for its practical engineering that balances performance, durability, and affordability in demanding settings:

- Rugged Plastic Housing — Modified high-temperature polymer resists strong acid/alkali corrosion and mechanical impact far better than glass bodies.

- Double-Junction Reference — Porous PTFE diaphragm reduces contamination and extends service life in dirty or precipitating solutions.

- Gel Electrolyte — Maintenance-free, no refilling required; minimizes leakage and drift.

- Integrated Temperature Compensation — NTC10K element for automatic correction, improving accuracy in variable-temperature processes.

- Fast and Stable Response — Low internal resistance (<250 MΩ) and high slope (>98%) deliver quick, repeatable readings.

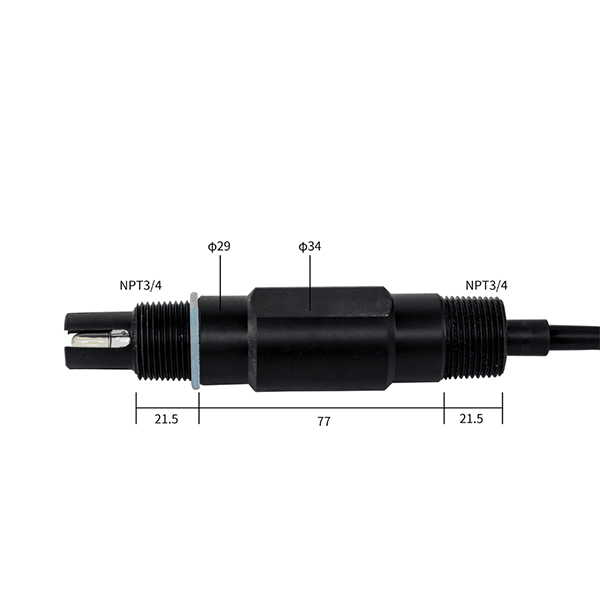

- Easy Installation — Standard 3/4″ NPT threading top and bottom; PG13.5 optional; 5–10 meter cable with BNC connector.

- Pressure and Temperature Tolerance — Up to 6 bar and 80°C continuous operation.

Specification

| Product | pH sensor |

| Model | PH5019 |

| Zero potential point | 7 ± 0.5 pH |

| Slope | > 98% |

| Membrane resistance | <250ΜΩ |

| Practical response time | < 1 min |

| Installation size | 3/4NPT |

| Measurement range | 1 ~ 14 pH |

| Salt bridge | Porous TEFLON |

| Temperature compensation | 10 KΩ/2.252KΩ/Pt100/Pt1000 |

| Temperature | 0 ~ 80℃ for general cables |

| Pressure | 1 ~ 3 Bar at 25 ℃ |

Applications

The PH5019 plastic pH value measurement tool is engineered for environments where chemical aggression, particulates, or mechanical stress rule out conventional glass electrodes:

- Wastewater and sewage treatment: Monitors neutralization, flocculation, and effluent pH in municipal and industrial plants.

- Mining and smelting operations: Handles acidic slurries and heavy-metal-laden streams.

- Papermaking and pulp processing: Tracks bleaching, stock preparation, and whitewater pH.

- Textile and dyeing industries: Resists dyes, bleaches, and alkaline finishes.

- Petrochemical and chemical production: Suitable for corrosive reactants, solvents, and process intermediates.

- Semiconductor and electronics manufacturing: Controls ultra-pure water rinses and etching baths.

- Biotechnology and pharmaceutical downstream processing: Ensures hygienic, contamination-resistant monitoring in fermentation and purification.