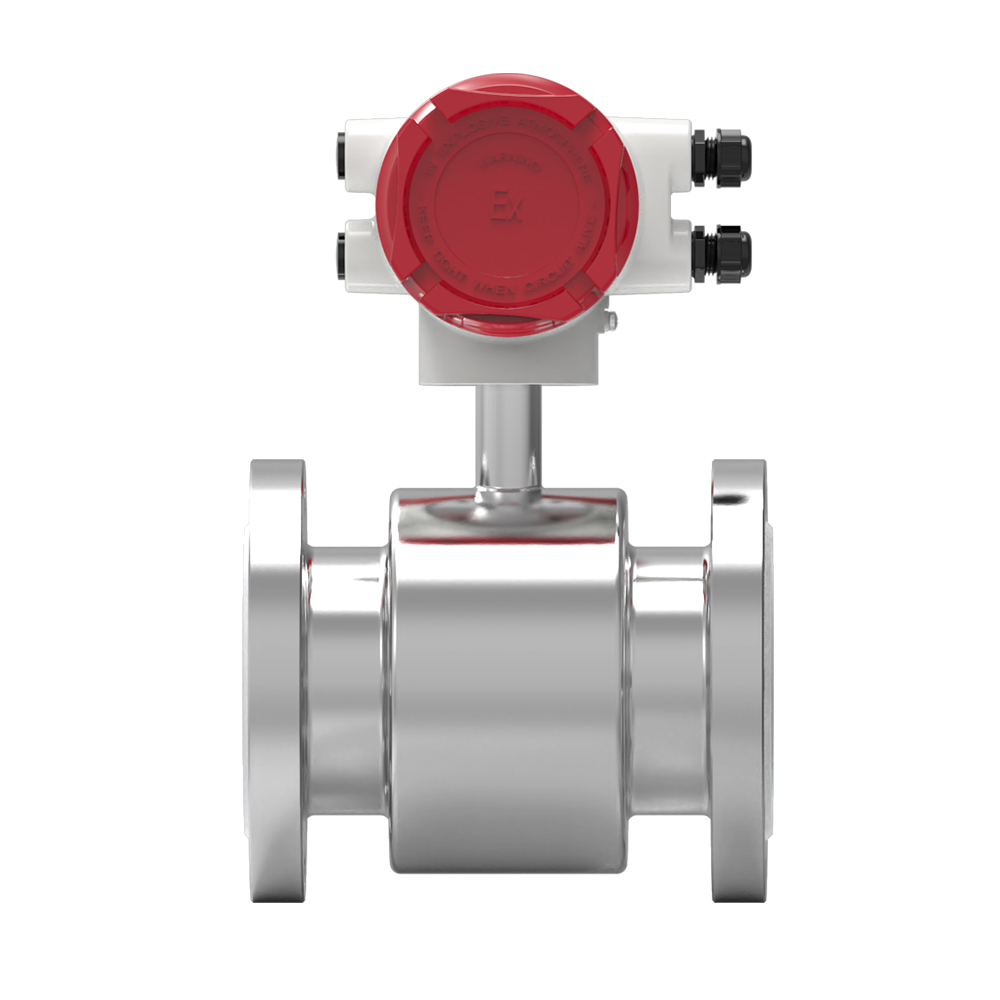

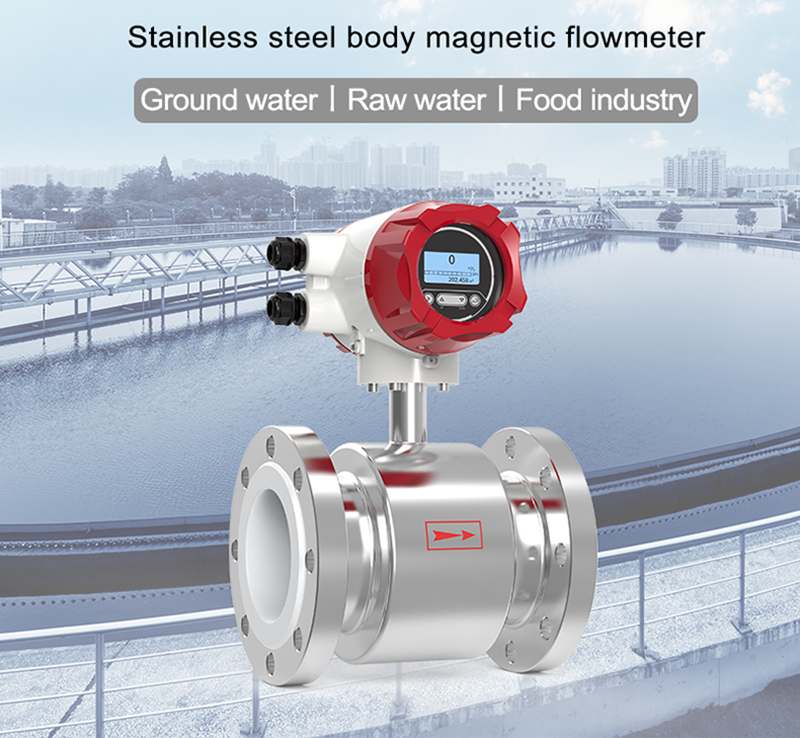

LDG Stainless Steel Body electromagnetic flowmeter

Introduction

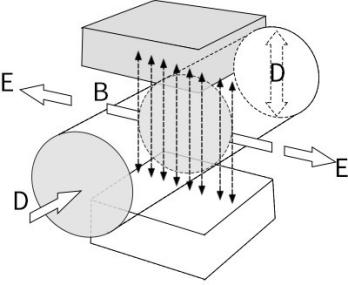

The LDG electromagnetic flowmeter operates on the principle of Faraday’s Law of Electromagnetic Induction, which states that a voltage is induced across a conductive liquid flowing through a magnetic field. This induced voltage is directly proportional to the liquid’s velocity, allowing the meter to measure flow rate without any moving parts accurately.

Engineered with a stainless steel body, the LDG offers excellent resistance to corrosion and wear, ensuring long-term performance in demanding environments. Its design supports both integral and split configurations, enabling flexible installation options to match different piping layouts and monitoring needs. The unit’s outputs, including analog, communication protocols, and relay controls, allow seamless integration with automation and process control systems.

With a broad nominal diameter range and compatibility with various liner and electrode materials, this flowmeter adapts to a variety of conductive media, including water, acids, alkalis, and slurries, maintaining dependable measurement across diverse industrial scenarios.

Working principle

Mag meter works based on Faraday’s law, and measures conductive medium with conductivity more than 5 μs/cm and flow range from 0.2 to 15 m/s. An Electromagnetic Flowmeter is a volumetric Flowmeter that measures the flow velocity of a liquid through a pipe.

The measurement principle of magnetic flowmeters can be described as follows: when the liquid goes through the pipe at the flow rate of v with a diameter D, within which a magnetic flux density of B is created by an exciting coil, the following electromotive force E is generated in proportion to the flow speed v:

E=K×B×V×D

| Where: E-Induced electromotive force K-Meter constant B-Magnetic induction density V-Average flow speed in the cross-section of the measuring tube D-Inner diameter of measuring tube |

|

Noted: the product is strictly prohibited from being used in explosion-proof occasions.

Key Features

The LDG stainless steel electromagnetic flowmeter offers the following key features to support reliable flow measuring:

-

Accuracy: Provides precise flow readings with an accuracy typically around ±0.5%, ensuring reliable data for process control and monitoring.

-

Durability: The rugged stainless steel construction offers enhanced corrosion resistance, extending the meter’s service life in harsh environments.

-

Wide applications: Suitable for all conductive liquids with conductivity typically above 5 μS/cm, including industrial water, wastewater, chemicals, and slurries.

-

Flexible installation: Available in both integral and split configurations, supporting installation in different piping setups.

-

Multiple output options: Supports analog signals, digital communication, and relay outputs for integration into control systems.

-

IP65 Protection: Designed with a high level of ingress protection to withstand challenging industrial environments.

-

Variety of liner and electrode choices: Compatible with materials such as PFA, PTFE, neoprene, as well as electrodes made of SUS316L, Hastelloy C, titanium, tantalum, and platinum alloys, enhancing adaptability to different media.

Specification

| Product | Electromagnetic flowmeter |

| Model | SUP-LDG |

| Diameter nominal | DN15~DN1000 |

| Nominal pressure | 0.6~4.0MPa |

| Accuracy | ±0.5%,±2mm/s(flowrate<1m/s) |

| Liner material | PFA, F46, Neoprene, PTFE, FEP |

| Electrode material | Stainless steel SUS316, Hastelloy C, Titanium, |

| Tantalum Platinum-iridium | |

| Medium temperature | Integral type: -10℃~80℃ |

| Split type: -25℃~180℃ | |

| Ambient Temperature | -10℃~60℃ |

| Electrical conductivity | Water 20μS/cm other medium 5μS/cm |

| Structure type | Tegral type, split type |

| Ingress protection | IP65 |

| Product standard | JB/T 9248-1999 Electromagnetic Flowmeter |

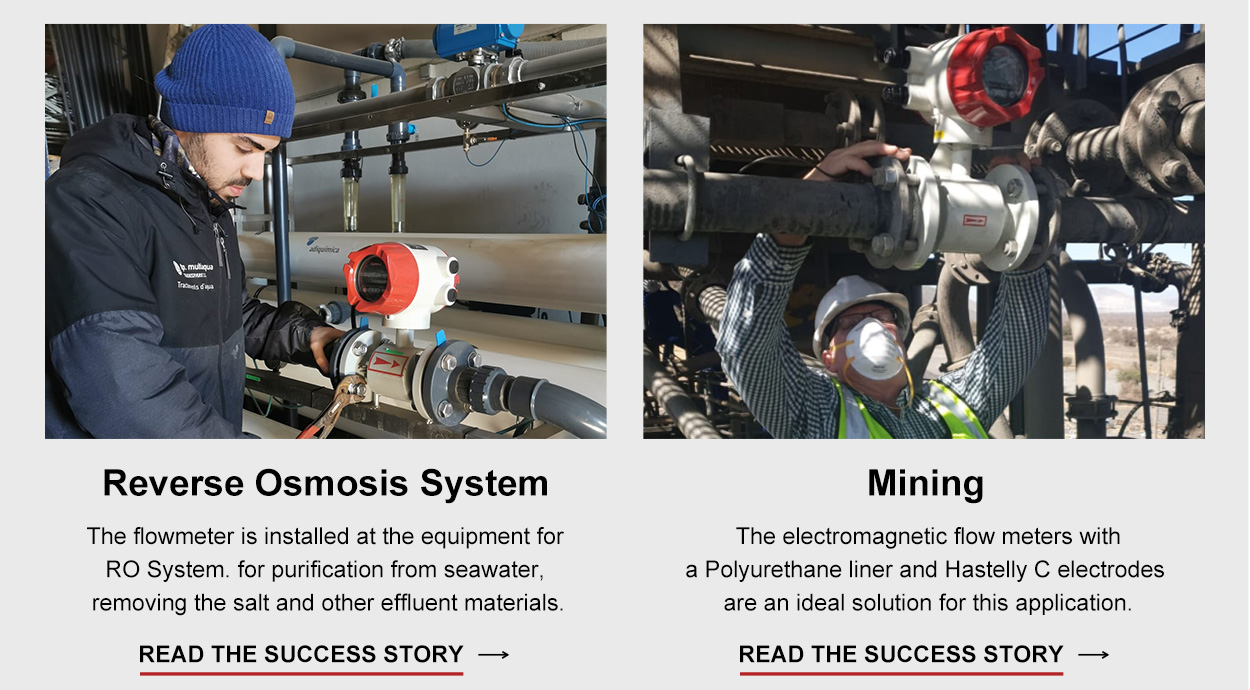

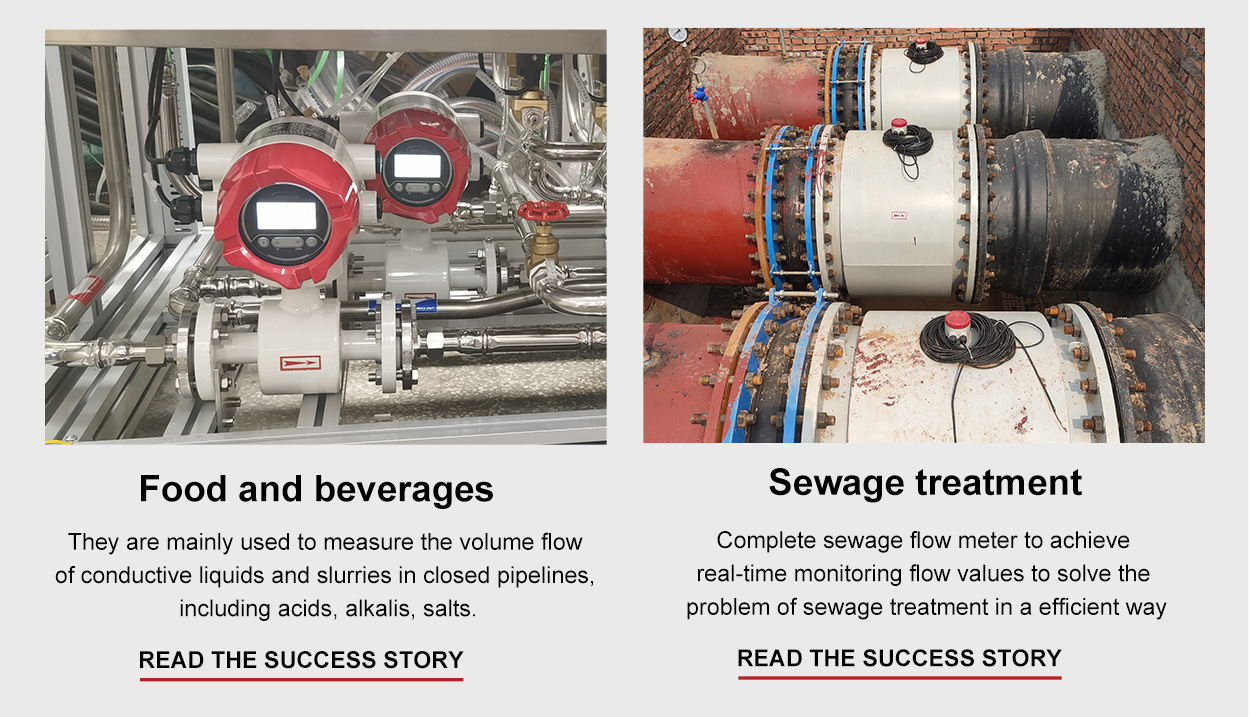

Application

The LDG stainless steel body electromagnetic flowmeter is used widely wherever accurate, reliable, and maintenance-free flow measurement is needed for conductive liquids:

-

Water and Wastewater Management: Flow monitoring and control in drinking water systems, wastewater treatment facilities, and distribution networks.

-

Chemical Processing: Measurement of aggressive or corrosive liquids in chemical plants, with optional electrode materials for enhanced resistance.

-

Food and Beverage Production: Ensuring hygienic, accurate flow measurement in processing lines where corrosion resistance and cleanliness are crucial.

-

Power Generation: Monitoring cooling water, boiler feedwater, and other conductive liquids in power plants to support efficient operation.

-

Pulp, Paper, and Mining: Handling slurries, process water, and other conductive fluids in heavy industrial environments.

-

Automated Systems: Integration with SCADA and process control systems for real-time flow data and automated adjustments.

Automatic calibration line