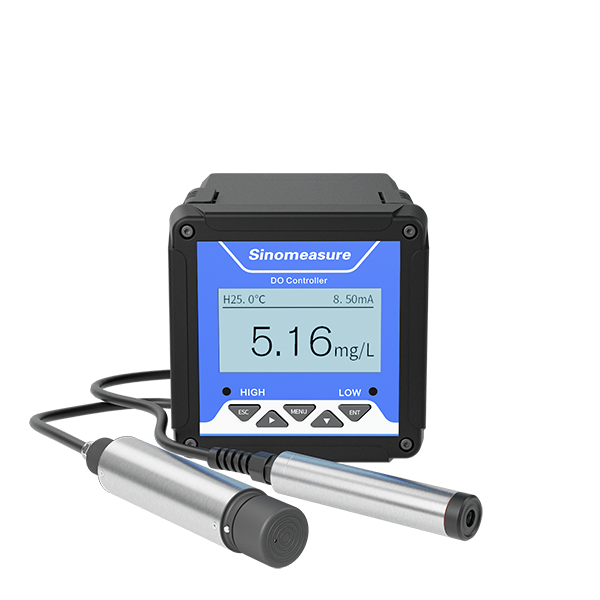

DY2900 Optical Dissolved Oxygen Controller for DO, Saturation, Oxygen Partial Pressure Measurement

Introduction

At the core of the DY2900 dissolved oxygen control instrument is an optical luminescence measurement principle, in which a luminescent chemical coating on the sensor interacts with dissolved oxygen molecules.

This optical approach offers significant advantages over traditional electrochemical sensors, including enhanced long-term stability, reduced maintenance needs, and minimal oxygen consumption during measurement.

The dissolved oxygen measuring supports multiple output options, making it easy to integrate into modern automation, SCADA, or data acquisition systems. Moreover, the DY2900 dissolved oxygen lineup includes configurable alarm settings and temperature compensation to ensure accuracy across varying environmental conditions.

Working routine display

The DY2900’s measurement process can be understood through three key operational stages:

Step 1: Optical excitation

The internal blue LED light source illuminates the oxygen-sensitive luminescent coating on the sensor tip. The coating absorbs this excitation light and emits red fluorescence.

Step 2: Oxygen Interaction

Dissolved oxygen molecules in the liquid interact with the luminescent material, quenching the emitted fluorescence. The extent of this quenching that is observed as changes in light intensity and decay time is directly related to the oxygen concentration.

Step 3: Signal Conversion and Output

The optical response is converted into electrical signals, which are processed by the meter’s internal circuitry to calculate DO concentration and saturation. These values are shown on the display and transmitted through configured analog or digital outputs for recording or control purposes.

Key features

The DY2900 is engineered to provide reliable, professional-grade dissolved oxygen measurement for industrial and environmental applications. Its key features include:

-

Optical luminescence sensing: Uses blue LED excitation and a luminescent sensor coating to detect DO through fluorescence quenching, ensuring stable and oxygen-non-consuming measurement.

-

Isolated outputs: Isolated transmitting output and RS485 communication help minimize electrical interference and maintain signal integrity in complex environments.

-

Multi-parameter detection: Simultaneous measurement of dissolved oxygen concentration, oxygen saturation (SAT), and temperature provides a comprehensive picture of water conditions.

-

Flexible communication interfaces: Supports 4–20 mA analog output, relay alarms, and isolated RS485 digital communication with Modbus-RTU protocol for seamless system integration.

-

Configurable alarms and display: Upper and lower limit alarms, delay settings, and configurable backlight/buzzer options improve visibility and operational control.

-

Temperature compensation: Integrated temperature measurement and compensation ensure accurate DO readings over a wide range of process conditions.

-

User-friendly calibration: Supports air calibration to facilitate on-site adjustments and maintain measurement accuracy over time.

Specification

| Product | Dissolved Oxygen meter |

| Model | DY2900 |

| Measure range | 0-20mg/L,0-200% |

| Resolution | 0.01mg/L,0.1%,1hPa |

| Accuracy | ±3%FS |

| Temperature Type | NTC 10k/PT1000 |

| Auto A/manual H | -10-60℃ Resolution;0.1℃ Correction |

| Correction accuracy | ±0.5℃ |

| Output Type 1 | 4-20mA output |

| Max. loop resistance | 750Ω |

| Repeatblitiy | ±0.5%FS |

| Output Type 2 | RS485 digital signal output |

| Communication protocol | Standard MODBUS-RTU(customizable) |

| Power supply | AC220V±10%50Hz,5W Max |

| Alarm relay | AC250V,3A |

Applications

The DY2900 Optical Dissolved Oxygen Meter is well-suited for continuous DO monitoring in a variety of industrial and environmental scenarios, including:

-

Wastewater Treatment:

Continuous DO measurement supports biological wastewater treatment optimization and ensures compliance with discharge standards. -

Environmental Water Monitoring:

Real-time oxygen data help assess the health of rivers, lakes, and reservoirs as part of ecological or regulatory programs. -

Industrial Process Control:

DO monitoring in cooling water systems, chemical processes, and water circuits helps prevent corrosion, scaling, and process inefficiencies. -

Aquaculture:

Maintaining appropriate dissolved oxygen levels is critical for aquatic animal health and growth. -

Drinking Water Treatment:

Monitoring oxygen supports corrosion control and quality management within potable water systems.