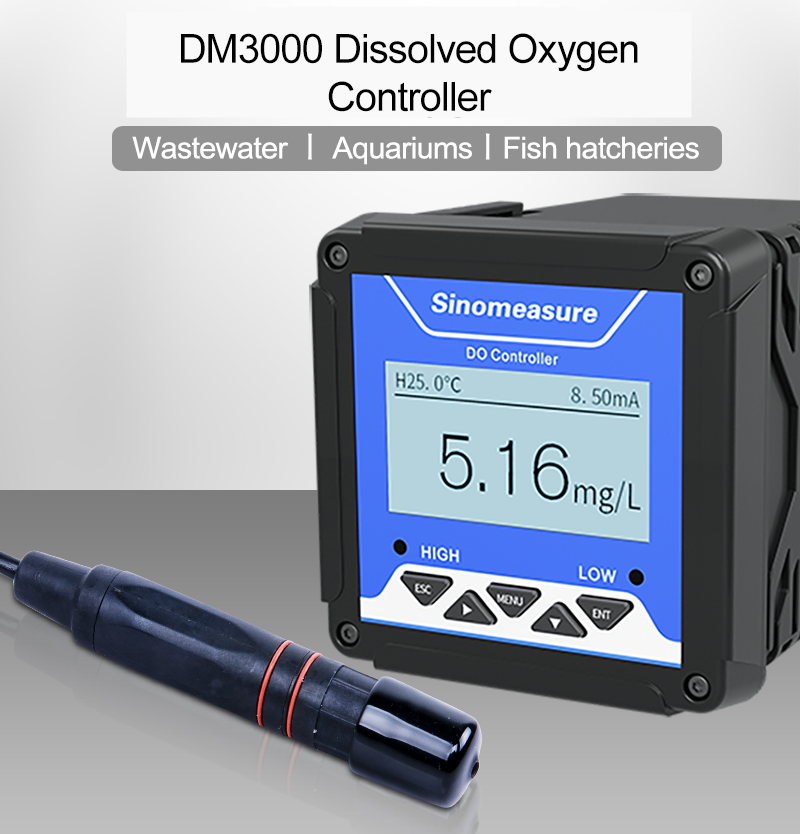

DM3000 Dissolved Oxygen Controller, DO Controller/Transmitter for Environmental/Process Control

Introduction

The DM3000 meter employs a polarographic electrochemical measurement principle, where the membrane electrode system senses the dissolved oxygen levels based on the resulting electrical current from oxygen reduction reactions.

The measured DO value is inherently affected by factors such as solution temperature, pressure, and salinity. The instrument includes a temperature measurement to support the accurate interpretation of DO data for precise readings.

Configured with a clear liquid crystal display, this dissolved oxygen controller responds with the simultaneous visualization. It also supports multiple output methods, including 4–20 mA analog output, relay control, and RS485 digital communication, which make it suitable for integration with automation systems and control networks.

Working routine

The DM3000 dissolved oxygen controller operates on the fundamental behavior of oxygen diffusion through a membrane and its subsequent electrochemical reduction:

Step 1: Membrane diffusion of oxygen

A selective membrane permits dissolved oxygen molecules from the process liquid to diffuse into the electrochemical sensor. This membrane separates the sample from the internal electrolyte while allowing oxygen to reach the reactive electrode surfaces.

Step 2: Electrochemical reduction reaction

Once oxygen enters the sensor chamber, it is reduced at the cathode electrode, typically generating a flow of electrons. Concurrently, oxidation occurs at the anode. The resulting electron flow (current) is directly proportional to the concentration of oxygen present in the solution. This mechanism is characteristic of membrane-based polarographic DO sensors and reflects the chemical activity of oxygen in the water.

Step 3: Signal conversion and display

The electrical current produced by the oxygen reduction reaction is converted by the meter’s internal circuitry into DO units (e.g., mg/L or % saturation). The liquid crystal display shows both DO and temperature values, while output signals can be transmitted to external controllers or data acquisition systems for further automation or process control.

Key features

The DM3000 is designed for robust performance and seamless integration in industrial environments with these impressive features:

-

Electrochemical membrane sensor: Provides accurate dissolved oxygen measurement using established polarographic principles.

- Wide measurement range: Capable of monitoring DO concentrations, saturation percentages, and related parameters across a broad range suitable for general industrial aqueous solutions.

-

Multi-output interfaces: Includes 4–20 mA analog output, relay alarms, and RS485 digital communication (MODBUS-RTU protocol) to support diverse system integration scenarios.

-

Dual display: The built-in liquid crystal display allows simultaneous viewing of dissolved oxygen and temperature values, aiding immediate interpretation at the point of installation.

-

Temperature measurement: Integrated temperature sensing ensures that variations in liquid temperature, a key factor influencing DO readings, are measured and presented along with DO data.

-

Industrial-grade construction: Engineered for stable and continuous operation in pipelines, tanks, or other liquid systems where long-term DO monitoring is required.

Specification

| Product | Dissolved Oxygen meter(Electrochemical type) |

| Model | DM3000 |

| Measure range | 0-40mg/L,0-130% |

| Accuracy | ±0.5%FS |

| Temperature accuracy | 0.5℃ |

| Output Type 1 | 4-20mA output |

| Max loop resistance | 750Ω |

| Repeatblitiy | ±0.5%FS |

| Output Type 2 | RS485 digital signal output |

| Communication protocol | Standard MODBUS-RTU(customizable) |

| Power supply | AC220V±10%, 5W Max, 50Hz |

| Alarm relay | AC250V,3A |

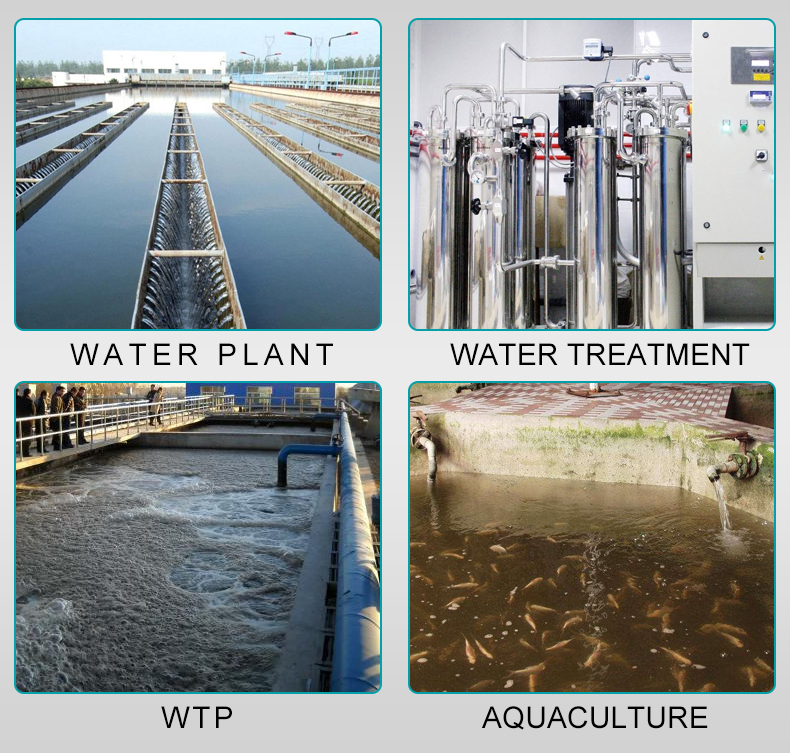

Applications

The DM3000 Electrochemical Dissolved Oxygen Meter is well-suited for a variety of industrial, environmental, and wastewater applications where dissolved oxygen is a critical control parameter:

-

Wastewater Treatment: Monitoring DO helps optimize aerobic biological processes, ensuring effective organic pollutant degradation.

-

Aquaculture Systems: In aquaculture, maintaining adequate dissolved oxygen is essential for aquatic animal health and growth, and real-time DO monitoring supports feeding and aeration control.

-

Environmental Water Quality Monitoring: Continuous DO measurement in rivers, lakes, and reservoirs assists in ecological assessment and early detection of oxygen depletion events.

-

Industrial Process Control: DO measurement is integral to processes like fermentation, chemical production, and cooling systems, where oxygen content impacts reaction efficiency or corrosion potential.

-

Drinking Water Treatment: Tracking dissolved oxygen levels can support corrosion control and post-treatment quality verification.