Turbine Flow Meters: Precision and Reliability for Modern Industries

As the global energy sector pivots toward cleaner fuels and stricter resource accountability, turbine flow meters remain a cornerstone for accurate flow measurement across various industries. These devices deliver exceptional precision, compliance with international standards, and cost-effective operation, making them vital for applications ranging from liquefied natural gas (LNG) custody transfer to sustainable aviation fuel (SAF) blending and chemical processing. This comprehensive guide explores how turbine flow meters work, their advantages, key applications, selection criteria, maintenance best practices, and their adaptation to emerging industry needs.

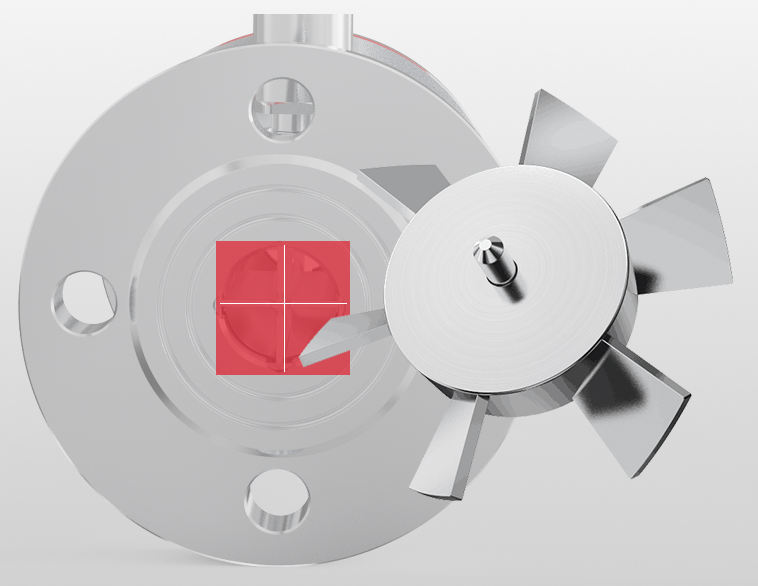

How Turbine Flow Meters Work

Turbine flow meters measure the flow rate of liquids or gases by leveraging the rotational speed of an internal turbine wheel. As fluid passes through the meter, it causes the turbine to spin at a rate proportional to the volumetric flow rate. Sensors detect the rotation, typically via magnetic or optical pickups, and convert it into an electronic signal for precise flow measurement.

When paired with advanced electronic signal converters, turbine flow meters provide fast, repeatable, and accurate readings, typically achieving ±0.5% to ±1% accuracy within their specified operating range. This makes them ideal for clean, low-viscosity fluids, such as water, fuels, solvents, and gases, used in industries where precision is critical.

Key Advantages of Turbine Flow Meters

The turbine meters offer several benefits that make them a preferred choice for industries requiring reliable flow measurement. Below are their primary advantages:

Exceptional Accuracy and Repeatability

Turbine flow meters deliver high accuracy, with repeatability as tight as ±0.5% and minimal long-term drift. This makes them suitable for critical applications like custody transfer, where precise measurement ensures fair financial transactions. They comply with stringent standards, such as API MPMS Chapter 5 (Petroleum Measurement Standards) and OIML R117 (Dynamic measuring systems for liquids), for custody transfer applications in oil, gas, and chemical industries.

Rapid Response Time

With response times under 100 milliseconds, turbine flow meters enable real-time monitoring and control in dynamic systems. This is particularly valuable in applications like fuel loading arms, batch processing, and automated dosing, where quick adjustments to flow changes are essential.

Compact Design and Cost Efficiency

Turbine flow meters feature a simple mechanical design, typically constructed with durable materials like stainless steel or Hastelloy. This simplicity translates to lower installation costs and reduced maintenance compared to more complex technologies, such as Coriolis or ultrasonic flow meters. Their compact size also makes them easy to integrate into existing systems.

Wide Operating Range

Turbine flow meters perform reliably across a broad range of pressures and temperatures, from cryogenic conditions as low as -200°C to high-temperature environments up to +400°C. Specialized models can handle pressures up to 10,000 psi (690 bar), making them suitable for demanding applications like LNG transfer or high-pressure hydrocarbon processing.

Industry Applications of Turbine Flow Meters

Turbine flow measurements are versatile and widely used across industries that demand precision and compliance. Below are some of their key applications:

LNG and Hydrocarbon Custody Transfer

As global energy markets evolve, with Europe diversifying its energy sources and Asia increasing LNG imports, turbine-type flow meters play a pivotal role in custody transfer operations. These meters ensure accurate measurement of liquefied natural gas (LNG), compressed natural gas (CNG), and refined hydrocarbons, supporting fair trade in high-value energy transactions.

Their compliance with international standards, including API, OIML, and ISO, ensures reliability in billion-dollar deals. For example, in LNG custody transfer, turbine flow meters provide the precision needed to account for every cubic meter of product, reducing financial disputes and ensuring regulatory compliance.

Aviation Fueling and Sustainable Aviation Fuel (SAF)

The aviation industry is under pressure to achieve net-zero emissions, driving demand for sustainable aviation fuel (SAF) alongside traditional jet fuels. Turbine flow meters are critical for precise fuel measurement during aircraft fueling operations, ensuring safety and efficiency.

Modern turbine meters are designed to handle the variable viscosity of SAF blends, incorporating advanced calibration techniques and temperature compensation algorithms. This enables them to maintain accuracy as tight as ±0.35% during blending operations, ensuring consistent performance whether measuring traditional kerosene-based fuels or eco-friendly SAF.

Chemical and Pharmaceutical Processing

In chemical and pharmaceutical industries, turbine flow meters support a range of critical processes, including:

-

Precision Batch Dosing: With repeatability as low as ±0.25%, turbine meters ensure accurate delivery of chemicals and reactants in batch processes, minimizing waste and ensuring product quality.

-

Solvent and Reactant Control: In pharmaceutical production, precise flow measurement is essential for controlling solvents and reactants, ensuring consistent formulations and compliance with regulatory standards.

-

Cooling and Circulation Systems: Turbine meters monitor flow in cooling systems for exothermic reactions, helping maintain safe operating conditions.

Their ability to handle clean, low-viscosity fluids makes them a go-to solution for these applications, where even minor deviations can impact product quality or process safety.

Selection Guidelines for Turbine Flow Meters

Choosing the right turbine flow meter requires careful consideration of several factors to ensure optimal performance. Below are key recommendations:

|

Factor |

Recommendation |

|---|---|

|

Fluid Viscosity |

Best suited for fluids with viscosity below 50 cSt (0–20 cSt is optimal). For higher-viscosity fluids, consider oval gear or Coriolis flow meters. |

|

Fluid Cleanliness |

Use a 100-micron pre-filter to protect turbine bearings from particulates. Avoid fibrous or abrasive media that could damage internal components. |

|

Calibration |

Opt for NIST-traceable calibration for custody transfer applications. Field calibration with proving systems is recommended for ongoing accuracy. |

|

Installation |

Ensure a minimum of 10 pipe diameters (10D) of straight pipe upstream and 5 pipe diameters (5D) downstream. Use flow conditioners in space-constrained setups to minimize turbulence. |

Proper selection ensures the meter operates within its optimal range, delivering reliable performance and longevity.

Maintenance Best Practices for Turbine Flow Meters

To maximize the lifespan and accuracy of turbine flow meters, regular maintenance is essential. Below are proven strategies to keep your meters in top condition:

Install Inline Filters

Using 100-micron stainless steel mesh filters prevents particulates from entering the meter and damaging turbine bearings. In clean fluid applications, this can extend the meter’s service life to five years or more. Inspect filters quarterly to prevent buildup that could restrict flow and affect measurement accuracy.

Prevent Cavitation and Pressure Spikes

Cavitation, caused by vapor bubble formation, can damage turbine blades and reduce accuracy. Maintain a minimum overpressure of 10% (or at least 1 bar) to prevent cavitation. In systems with quick-closing valves, install pressure dampeners to mitigate pressure spikes. For applications involving reciprocating pumps, consider pulsation dampeners to smooth out flow variations.

Schedule Regular Calibration

For custody transfer applications, recalibrate turbine flow meters annually using master meters or provers to maintain compliance with standards. In general process control applications, calibration every 2–3 years is typically sufficient. Always recalibrate after significant maintenance or if you notice accuracy drifting beyond acceptable tolerances (e.g., ±1%).

Adapting to Modern Industry Demands

Turbine flow meters have evolved to meet the challenges of modern industries, incorporating advanced materials and technologies to enhance performance. Key innovations include:

-

Cryogenic Materials: Meters constructed with stainless steel 316L or Monel are designed for LNG applications at temperatures as low as -162°C, ensuring durability in extreme conditions.

-

Corrosion-Resistant Construction: Hastelloy C-276 is used for meters handling corrosive biofuels, chemicals, or solvents, extending service life in aggressive environments.

-

Digital Integration: Modern turbine meters support digital communication protocols like Modbus, HART, and Foundation Fieldbus, enabling seamless integration with Industry 4.0 systems for real-time data monitoring and analytics.

These advancements make turbine flow meters a future-proof solution for industries navigating the transition to cleaner fuels and smarter manufacturing processes.

Conclusion

Turbine flow meters combine precision, reliability, and cost-effectiveness, making them a versatile choice for industries ranging from energy to aviation to chemical processing. Their ability to deliver accurate measurements in demanding conditions, comply with global standards, and integrate with modern digital systems ensures they remain a trusted tool for professionals worldwide.

Whether you’re managing LNG custody transfer, fueling aircraft with sustainable aviation fuel, or controlling chemical dosing, turbine flow meters provide the performance and dependability needed to meet today’s challenges. By following proper selection, installation, and maintenance practices, you can ensure these meters deliver consistent results for years to come.

Post time: Sep-18-2025