How Our Optical Dissolved Oxygen Controller Supports Ford Automobile’s Process Systems

Precise dissolved oxygen control plays a critical role in modern industrial manufacturing processes. In automotive production, stable and accurate dissolved oxygen measurement helps ensure consistent water quality, process efficiency, and environmental compliance. This article introduces how our DY2900 Optical Dissolved Oxygen Controller has been applied in Ford Automobile, explains its role and working logic in real-world use, and outlines the broader industrial applications of dissolved oxygen controllers and sensors.

Our DY2900 Optical Dissolved Oxygen Controller Exerts a Great Influence on Ford Automobile

In automotive manufacturing plants such as Ford Automobile, water systems are widely used for cooling, surface treatment, wastewater treatment, and auxiliary production processes. Maintaining stable dissolved oxygen (DO) levels is essential to prevent corrosion, control microbial activity, and ensure compliance with environmental discharge standards.

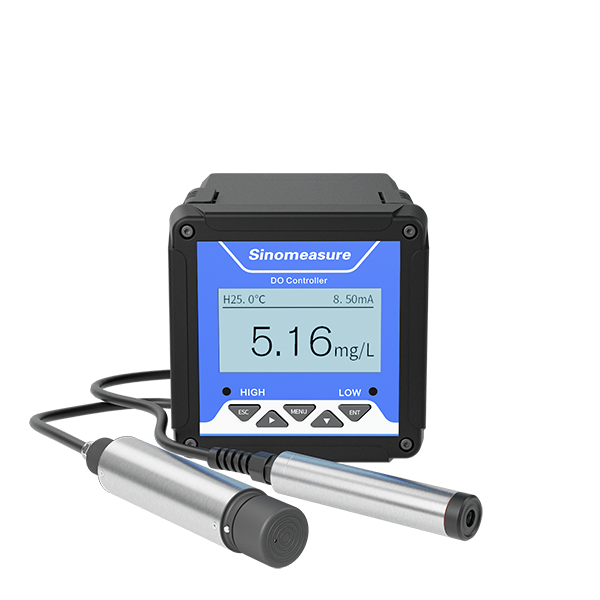

The DY2900 Optical Dissolved Oxygen Controller was introduced to support continuous DO monitoring in Ford’s process systems. Its optical measurement technology enables stable and reliable oxygen detection without the frequent maintenance typically associated with traditional electrochemical sensors. This helps reduce manual intervention while ensuring consistent process control.

In practical operation, the DY2900 dissolved oxygen controller works together with optical dissolved oxygen sensors to provide real-time DO values, temperature data, and alarm signals. These outputs are integrated into the plant’s existing control system, enabling operators to respond promptly to fluctuations in oxygen levels. As a result, Ford’s production systems benefit from improved monitoring accuracy, reduced downtime, and more predictable water quality management.

More Details about the DY2900 Optical Dissolved Oxygen Controller

Rather than functioning as a standalone measuring device, the DY2900 dissolved oxygen measurement serves as a central controller that processes, displays, and transmits dissolved oxygen data in continuous industrial applications.

It is designed for long-term online monitoring. It supports optical DO sensors and provides stable measurement performance in environments where temperature variation, humidity, or chemical interference may affect traditional sensors.

Working Theory

The DY2900 operates based on optical dissolved oxygen measurement principles, following three core steps:

Step 1: Optical Signal Generation

The optical sensor emits light onto a sensing material that reacts to dissolved oxygen in the liquid.

Step 2: Oxygen-Dependent Signal Response

The presence of oxygen affects the light signal predictably, allowing oxygen concentration to be determined without oxygen consumption.

Step 3: Signal Processing and Output

The controller processes the signal and converts it into readable dissolved oxygen values, temperature data, and standard output signals for monitoring and control systems.

This non-consumptive measurement approach contributes to long-term stability and reduced maintenance.

Highlights and Specifications

The DY2900 optical dissolved oxygen controller adopts an optical measurement method that delivers strong long-term stability, making it well-suited for continuous industrial operation.

It supports online dissolved oxygen monitoring and provides a clear display of both dissolved oxygen and temperature values, allowing operators to quickly understand real-time process conditions. With standard signal outputs, the controller integrates easily into common industrial control systems, while its alarm and control functions support automated operation and timely response to abnormal conditions.

From a system perspective, the DY2900 dissolved oxygen transmitter is designed for online dissolved oxygen measurement in combination with optical DO sensors. Its industrial-grade enclosure ensures reliable performance during continuous operation, and its compatibility with widely used control and automation systems allows for flexible deployment across different industrial applications.

These characteristics make the DY2900 well-suited for automotive manufacturing environments, where reliability and data consistency are essential.

The Wide Applications of Dissolved Oxygen Controllers and Sensors

Beyond automotive manufacturing, dissolved oxygen controllers and sensors are widely used across multiple industries where water quality and process control are critical. The typical application areas include:

-

Industrial wastewater treatment for aeration control and discharge compliance

-

Cooling water and circulating water systems to prevent corrosion and biofouling

-

Chemical and pharmaceutical production for process consistency

-

Power plants and energy facilities for boiler and cooling water monitoring

-

Environmental monitoring in surface water and effluent systems

The successful application of the DY2900 optical dissolved oxygen controller at Ford Automobile demonstrates how accurate DO monitoring supports operational efficiency, environmental responsibility, and process stability in modern industrial facilities.

By combining optical measurement technology with reliable control and integration capabilities, the DY2900 supports consistent process performance and efficient water quality management. More broadly, this case highlights how dissolved oxygen controllers and sensors play an essential role across industries where operational stability, automation, and environmental responsibility are key priorities.

Post time: Jan-13-2026