Master Pressure Instrumentation with Animated Guides

Your quick pathway to becoming a measurement expert. Explore the core principles of pressure measurement with visual clarity.

Introduction to Pressure Instrumentation

Understanding pressure instrumentation is fundamental in various industrial applications, from process control to safety systems. This guide provides a clear overview of common pressure measurement devices, their working principles, and typical applications. Each section is designed to simplify complex concepts, making learning efficient and engaging.

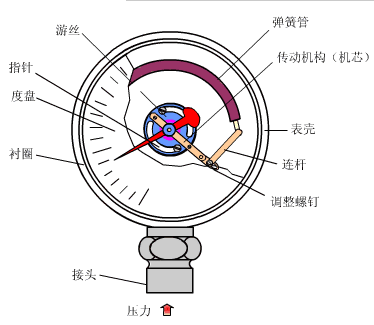

1. Bourdon Tube Pressure Gauge

Commonly utilized in industrial systems, such as boilers, Bourdon tube pressure gauges operate on the principle of a curved, hollow tube that deforms under internal pressure.

Working Principle:

- Pressurized fluid enters the curved Bourdon tube.

- The tube slightly straightens, transferring this movement through a system of:

- Connecting rod

- Segment and pinion gear

- Pointer and dial

- The pointer then precisely displays the pressure value on a calibrated dial.

Accuracy Grade:

Accuracy is defined as a percentage of the full scale of the allowable error.

- Common grades include: 0.5, 1.0, 1.5, 2.0, and 2.5.

- A lower grade number signifies higher accuracy.

- Grades 3 and 4 are rarely employed in critical applications like boiler systems due to their lower precision.

2. Electric Contact Pressure Gauge

This instrument is an enhanced version of the Bourdon pressure gauge, integrating electric contacts to provide crucial alarm and control functionalities.

Features:

- Equipped with both upper and lower limit contacts.

- Triggers an alarm or an automatic response when pressure thresholds are exceeded.

- Can be seamlessly integrated with relays and contactors for comprehensive automatic control.

- Particularly applicable in demanding environments such as oil and gas boiler systems.

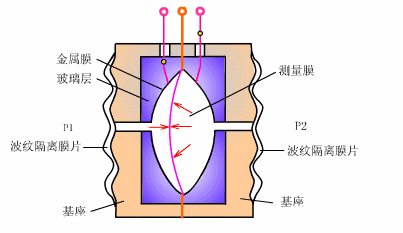

3. Capacitive Pressure Sensor

These sophisticated sensors detect pressure by accurately measuring the change in capacitance resulting from the deformation of a flexible diaphragm.

Working Principle:

- Applied pressure causes the flexible diaphragm to displace.

- This displacement directly alters the capacitance between two plates.

- The resulting signal is then accurately converted into a measurable electrical output.

Types:

- Available in both single-ended and differential designs.

- Differential pressure sensors typically exhibit approximately twice the sensitivity of single-ended types.

Advantages:

- High sensitivity, enabling precise measurements.

- Fast response speed for dynamic applications.

- Excellent resistance to shock and vibration.

- Simple and robust structural design.

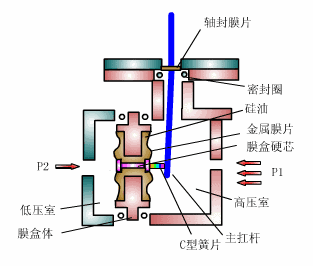

4. Bellows Pressure Gauge

This gauge is an ideal choice for measuring subtle pressure changes, particularly suited for boiler ventilation systems and gas pipelines.

Working Principle:

- Pressure enters the specialized bellows cavity.

- The bellows expand, generating a precise mechanical displacement.

- This motion is then accurately transmitted to a pointer via a gear mechanism.

- A live pressure reading is displayed directly on the instrument’s dial.

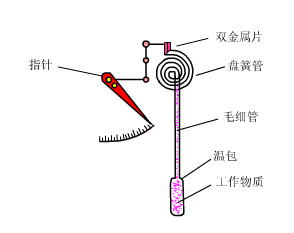

5. Pressure Thermometers

These integrated instruments utilize a sealed system filled with a specific fluid to precisely convert temperature changes into corresponding pressure readings.

Components:

- A sphere (probe) strategically placed within the temperature zone to be monitored.

- A capillary tube designed to carry the pressure changes.

- A Bourdon tube, which reacts to the changes in pressure transmitted.

- A pointer that accurately indicates the temperature on a calibrated dial.

Fluids Used:

- Commonly filled with liquids, steam, or gases such as nitrogen (chosen for its stability).

- Operating range typically spans from -100°C to +500°C.

Applications:

- Essential for continuous temperature monitoring and automatic switching functions.

- Widely used for control circuits within diverse industrial systems.

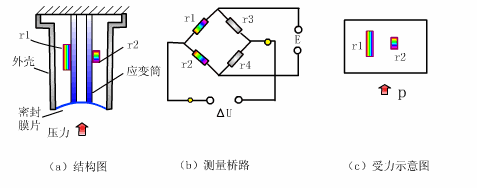

6. Strain Gauge Pressure Sensors

These highly precise sensors leverage strain gauges to convert mechanical strain directly into measurable changes in electrical resistance.

Key Elements:

- A strain gauge meticulously bonded to a pressure-sensitive substrate.

- The substrate deforms under applied pressure, thereby altering the resistance of the strain gauge.

- Typically employs a Wheatstone bridge circuit for accurate measurement of resistance changes.

- The resulting signal is then amplified and digitized for precise output.

Variations:

- Available in both metal foil and semiconductor types.

- Metal foil types further include wire and foil subtypes.

Use Cases:

- Excellent for seamless integration into modern digital control systems.

- Offers high accuracy and is well-adapted for dynamic measurement applications.

Conclusion: Visual Learning, Hands-on Skills

Whether you’re new to instrumentation or simply refreshing your knowledge, these animated pressure instrumentation guides are designed to help you quickly grasp core concepts and build practical understanding.

Stay tuned for more simplified guides on level, flow, and analytical instrumentation—all crafted to make learning automation not only informative but also genuinely enjoyable.

Connect with Our Experts

Have questions or need further insights into instrumentation solutions for your business? We’re here to help.

© 2025 Instrumentation Insights. All rights reserved.

Post time: May-22-2025