Industrial Load Cell Solutions: Precision Weighing Guide

Leading manufacturers like Mettler Toledo and HBM set the standard for reliable weight measurement in industrial automation systems.

Understanding Load Cell Technology

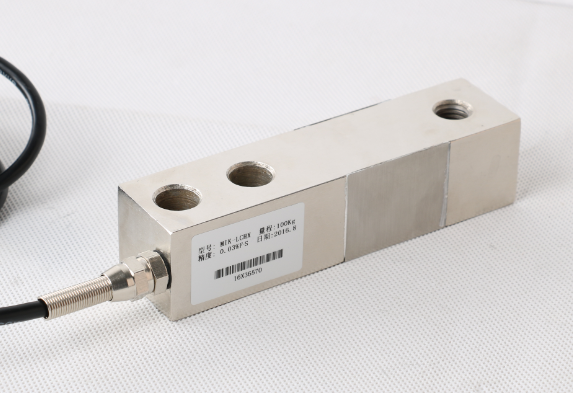

A load cell is a precision transducer that converts mechanical force into an electrical signal, enabling accurate weight measurement in industrial environments. Unlike commercial scales, industrial load cells are designed for harsh conditions and continuous operation.

Load Cell Types and Applications

S-Type Load Cells

Named after their “S” shape, S-Type load cells are commonly used in crane scales and tension/compression measurements. Equipped with eye bolts, they can suspend loads or integrate directly into machinery. Standard models typically handle up to 5 tons, making them a popular choice for suspended or mechanical weighing systems.

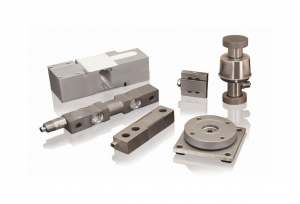

Pancake Load Cells

Also called pancake load cells, these sensors feature a wheel-shaped design with multiple bolt holes for stable installation. They are ideal for tension/compression applications and tank weighing systems, providing accurate weight measurement even under dynamic conditions.

Signal Processing and Integration

Weighing Indicators

- Real-time weight display

- Programmable alarms

- Multi-unit conversion

Signal Transmitters

- Convert mV to 4-20mA/0-10V

- PLC/SCADA integration

- Long-distance transmission

Standard load cells output 2mV/V signals (e.g., 20mV at 10V excitation), requiring amplification for industrial control systems.

Need Professional Guidance?

Our engineers have 20+ years experience in industrial weighing solutions

Post time: Apr-29-2025