Understand Pressure Types in Automation: Gauge, Absolute, and Differential – Choose the Right Sensor Today

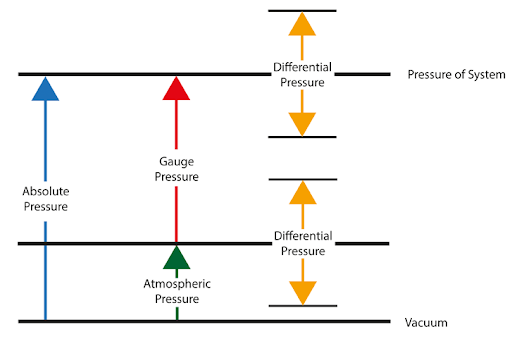

In process automation, accurate pressure measurement is vital for system safety, performance, and efficiency. But not all pressure readings are the same. To optimize your setup, you must understand the differences between gauge pressure, absolute pressure, and differential pressure—each with unique reference points and use cases. This guide simplifies the differences and helps you select the right sensor for your application.

What Is Gauge Pressure?

Gauge pressure (Pgauge) measures the pressure relative to local atmospheric pressure. Most industrial and everyday instruments—like tire gauges and hydraulic systems—display gauge pressure.

Formula:

Pgauge = Pabs − Patm

Use Cases:

Pneumatics, tire inflation, water pumps

Note: Gauge pressure can be negative (vacuum) or positive.

✔ Ideal for: General industrial monitoring where ambient pressure is stable.

What Is Absolute Pressure?

Absolute pressure (Pabs) is measured against a perfect vacuum. It accounts for both atmospheric pressure and gauge pressure, providing a true, fixed reference—especially critical in scientific or high-precision contexts.

Formula:

Pabs = Pgauge + Patm

Use Cases:

Aerospace, thermodynamics (e.g., gas laws), vacuum systems

✔ Ideal for: Applications requiring high accuracy across different altitudes.

What Is Differential Pressure?

Differential pressure (ΔP) is the difference between two pressure points within a system. It’s not tied to atmospheric pressure and is essential for detecting flow, resistance, or level differences.

Formula:

ΔP = PA − PB

Use Cases:

Flow meters, filters, tank level monitoring

✔ Ideal for: Process control, flow rate calculations, HVAC balancing.

Choosing the Right Pressure Sensor

Whether you’re calibrating a vacuum chamber, maintaining optimal airflow, or monitoring a closed-loop hydraulic system, choosing the right pressure type matters:

- Use absolute pressure sensors for precision in changing environments.

- Use gauge sensors for daily process operations.

- Use differential transmitters for measuring internal variations across components.

Final Thoughts: Optimize Your System with the Right Pressure Insights

Understanding pressure measurement types ensures accurate data, safer operations, and better control. Don’t let a mismatch between sensor and pressure type compromise your system.

Need help selecting the right sensor for your process? Contact our experts today for tailored guidance.

Post time: May-20-2025