Electrical Conductivity Meter: A Comprehensive Guide for Beginners

In the modern context of quality control, environmental monitoring, and specialized manufacturing, the ability to accurately assess fluid composition is paramount. Electrical conductivity (EC) stands as a fundamental parameter, offering critical insight into the total concentration of dissolved ionic material within a solution. The electrical conductivity meter (EC Meter) is the indispensable analytical instrument used to quantify this property.

This comprehensive guide is designed for professionals and beginners alike, providing a rigorous breakdown of the EC meter’s principles, function, calibration, and diverse applications, ensuring beginners can confidently integrate this essential measurement technique into their operational workflow.

Table of Contents:

1. What is Electrical Conductivity?

2. What is an Electrical Conductivity Meter?

3. What’s the Working Principle of the Electrical Conductivity Meter?

4. What Does an Electrical Conductivity Meter Measure?

5. All Sorts of Electrical Conductivity Meters

6. How to Calibrate an Electrical Conductivity Meter?

7. Wide Applications of the Electrical Conductivity Meter

8. What’s the Difference Between an Electrical Conductivity Meter and a pH Meter?

I. What is Electrical Conductivity?

Electrical conductivity (κ) is the measure of a substance’s ability to transmit an electric current. In aqueous solutions, this transmission is achieved not by free electrons (as in metals) but by the movement of dissolved ions. When salts, acids, or bases are dissolved in water, they dissociate into positively charged cations and negatively charged anions. These charged particles enable the solution to conduct electricity.

In general, conductivity (σ) is mathematically defined as the reciprocal of resistivity (ρ), indicating a material’s capacity to conduct an electric current (σ = 1/ρ).

For solutions, the conductivity is directly dependent on ion concentration; simply, a higher concentration of mobile ions directly results in higher conductivity.

While the standard international unit (SI Unit) for conductivity is Siemens per meter (S/m), in practical applications like water quality analysis and laboratory analysis, the values micro-Siemens per centimeter (µS/cm) or milli-Siemens per centimeter (mS/cm) are more common and widely used.

II. What is an Electrical Conductivity Meter?

An electrical conductivity meter is a precise analytical device engineered to measure the conductivity of a solution, which operates by applying an electric field and quantifying the resulting current flow.

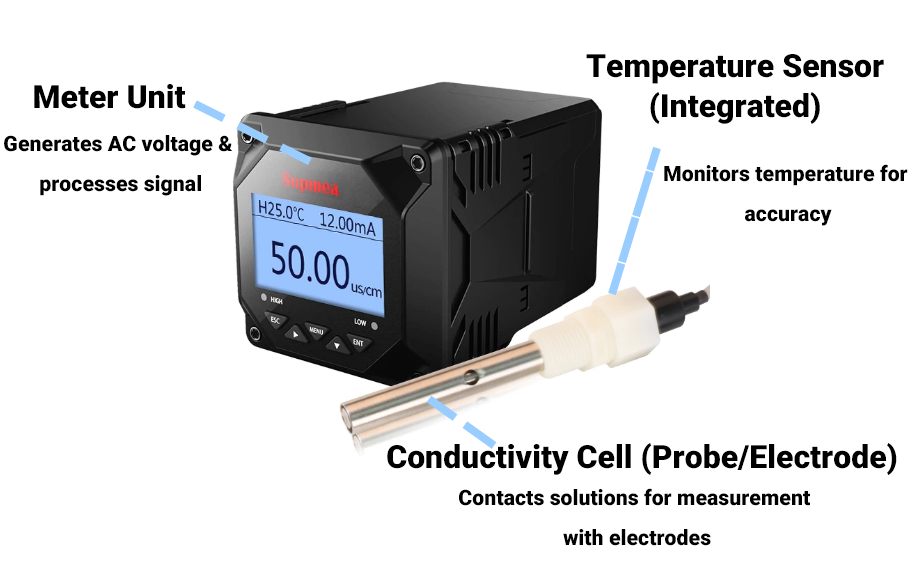

The instrument typically comprises three main functional units:

1. The conductivity cell (probe/electrode): This is the sensor that contacts the targeted solution. It contains two or more electrodes (often made of platinum, graphite, or stainless steel) separated by a fixed distance.

2. The meter unit: This is the electronic component that generates the excitation voltage (AC) and processes the sensor signal.

3. The temperature sensor: This necessary component is often integrated into the probe to measure the sample temperature for accurate compensation.

The EC meter provides the essential data required for managing processes where dissolved solids concentration is critical, such as water purification and chemical manufacturing.

III. What’s the Working Principle of the Electrical Conductivity Meter?

The measurement principle relies on the relationship between conductance and resistance, mediated by a fixed geometry. Here, let’s explore the core measurement steps together:

1. AC Voltage application: The meter applies a precise, known alternating current (AC) voltage across the two electrodes in the probe, which prevents polarization and degradation of the electrode surfaces.

2. Current measurement: The electrical conductivity meter measures the magnitude of the current (I) that flows through the solution, and this current is proportional to the concentration of mobile ions.

3. Conductance calculation: The electrical conductance (G) of the solution between the two plates is calculated using a rearranged form of Ohm’s Law: G = I/V.

4. Conductivity determination: To obtain the specific conductivity (κ), the measured conductance (G) is multiplied by the probe’s cell constant (K): κ = G · K. The cell constant (K) is a fixed geometric factor defined by the distance (d) between the electrodes and their effective surface area (A), K = d/A.

Conductivity is highly sensitive to temperature; a 1°C increase can raise the reading by approximately 2-3%. To ensure results are comparable globally, all professional EC meters utilize Automatic Temperature Compensation (ATC).

The meter references the measured conductivity value to a standard temperature, typically 25°C, using a defined temperature coefficient, ensuring the reported value is accurate regardless of the sample’s actual temperature during the measurement.

IV. What Does an Electrical Conductivity Meter Measure?

While the EC meter’s fundamental output is Electrical Conductivity, this reading is routinely used to quantify or estimate other critical water quality parameters in sorts of industrial plants:

1. Electrical Conductivity (EC): The direct measurement, reported in µS/cm or mS/cm.

2. Total Dissolved Solids (TDS): TDS represents the total mass of dissolved organic and inorganic matter per unit volume of water, typically expressed in mg/L or parts per million (ppm). Since EC is strongly correlated with the ionic content (the largest fraction of TDS), the EC meter can provide an estimated TDS value using a conversion factor (TDS Factor), commonly ranging from 0.5 to 0.7.

3. Salinity: For brackish water, seawater, and industrial brines, EC is the primary determinant of salinity, which is the total concentration of all salts dissolved in the water, typically reported in PSU (Practical Salinity Units) or parts per thousand.

V. All Sorts of Electrical Conductivity Meters

EC meters in various configurations are designed to meet the specific requirements of accuracy, mobility, and continuous monitoring, and here are the common types of conductivity meters that are frequently seen in sorts of industrial scenes:

| Meter Type | Primary Features | Typical Applications |

|---|---|---|

| Benchtop (Laboratory Grade) | Highest precision, multi-parameter (often combined with pH), data logging, GLP/GMP compliance. | Research and Development labs, pharmaceutical testing, and quality assurance. |

| Portable (Field Grade) | Rugged, battery-operated, integrated data memory, suitable for harsh environments. | Environmental surveys, agricultural testing, and hydrology studies. |

| Online/Industrial | Continuous, real-time measurement in pipelines or tanks, alarm functions, 4-20mA outputs for PLC/DCS control. | Boiler feedwater, cooling tower control, ultra-pure water systems. |

| Pocket (Pen Conductivity Meter) | Smallest, simplest operation, generally lower accuracy, and cell constant. | Home use, aquaculture, and basic TDS checks for drinking water. |

VI. How to Calibrate an Electrical Conductivity Meter?

Regular calibration is mandatory to maintain the accuracy and reliability of any EC measurement system. Calibration standardizes the meter’s response to known values, verifying the cell constant (K).

Standard Calibration Procedure:

1. Standard Selection: Select a certified conductivity standard solution (e.g., potassium chloride (KCl) solutions with known values like 1413 µS/cm or 12.88 mS/cm) that brackets your expected sample range.

2. Probe Preparation: Rinse the electrode thoroughly with deionized (DI) water and then with a small amount of the standard solution to condition the surface. Blot dry with lint-free paper; do not wipe aggressively.

3. Measurement: Immerse the probe completely into the standard solution, ensuring no air bubbles are trapped near the electrode surfaces. Allow the temperature to stabilize.

4. Adjustment: Initiate the meter’s calibration function. The device will automatically read the stabilized value and internally adjust its parameters (or prompt the user to input the known standard value).

5. Verification: For high-precision work, verify the calibration using a second, different standard solution.

VII. Wide Applications of the Electrical Conductivity Meter

The applications of EC measurement are widespread and critical across various sectors:

1. Water Purification: Monitoring the efficiency of Reverse Osmosis (RO) and deionization systems. The conductivity of ultra-pure water is a direct measure of its quality (low µS/cm indicates high purity).

2. Environmental Science: Assessing the overall health and salinity of natural water bodies (rivers, lakes, groundwater), often used as an indicator of potential pollution or mineral runoff.

3. Agriculture and Horticulture: Controlling the nutrient solution concentration in hydroponics and fertigation. Plant health is directly linked to the EC level of the feeding water.

4. Industrial Process Control: Regulating blowdown cycles in cooling towers and boilers to prevent scale and corrosion by maintaining the concentration of dissolved solids within acceptable limits.

5. Food and Beverage: Quality control, used to measure the concentration of ingredients (e.g., salt in brine solutions or acid concentration in beverages).

VIII. What’s the Difference Between an Electrical Conductivity Meter and a pH Meter?

While both are essential tools for liquid analysis, the EC meter and the pH meter measure fundamentally distinct characteristics of a solution:

| Feature | Electrical Conductivity Meter (EC Meter) | pH Meter |

|---|---|---|

| What it measures | The capacity of the solution to conduct current, determined by the total mobile ion concentration |

The concentration (activity) of hydrogen ions (H+) |

| What it indicates | Total dissolved solids, salinity, and purity | Acidity or alkalinity |

| Principle | Measurement of electrical current under a known voltage | Measurement of the potential difference across a pH-sensitive glass membrane |

| Units | µS/cm or mS/cm | pH units (a logarithmic scale from 0 to 14) |

In a comprehensive water analysis, both parameters are necessary. For instance, while high conductivity tells you there are many ions present, the pH tells you if those ions are predominantly contributing to acidity or alkalinity.

Post time: Nov-04-2025