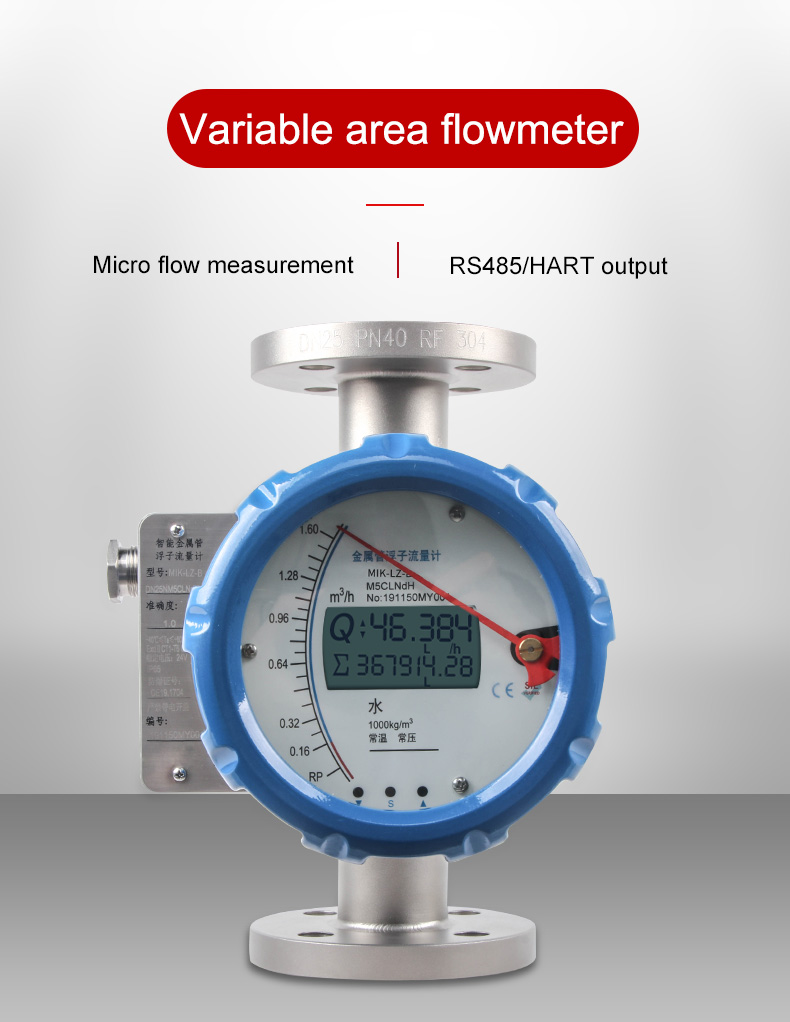

SUP-LZ Rotameter and Flow Meter, Rotameter Flow Indicator for Liquids Measurement

Introduction

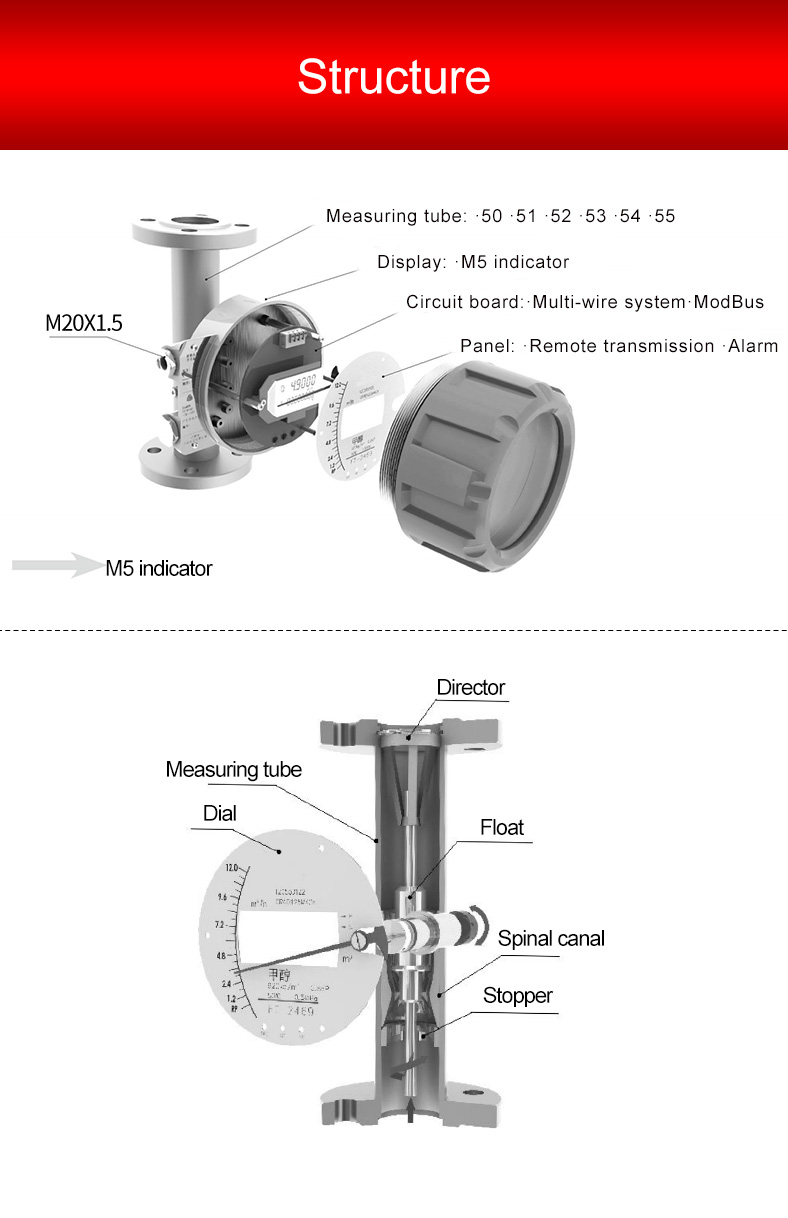

The SUP-LZ tube rotameter provides proven, low-maintenance volumetric flow measurement using the variable area principle. Fluid enters the bottom of a vertically mounted, precision-tapered metal tube and lifts a shaped float until drag and buoyancy forces balance the float’s weight.

The resulting annular area, the float’s height, is directly proportional to the flow rate. Position is transferred magnetically to an external mechanical indicator or converted into 4–20 mA, HART, pulse, or alarm signals for seamless integration with control systems. Minimal pressure drop, excellent repeatability, and insensitivity to moderate changes in viscosity or density make it exceptionally reliable in real-world process conditions.

How Does an LZ Metal Tube Rotameter Work?

Process fluid flows upward through the tapered metal tube, raising the float to an equilibrium position determined by flow rate. Higher flow lifts the float higher, increasing the annular clearance and maintaining force balance.

Magnetic coupling transmits this position safely to the external scale or transmitter without any seals or packing glands in contact with the medium, ensuring long-term stability even with aggressive fluids.

Key Features

What makes the SUP-LZ rotameter flow indicator remarkable is its integration of industrial-grade durability and advanced functionality that adapts to virtually any process requirement. Here are the standout specifications and capabilities that make it a preferred choice for engineers worldwide:

- Excellent Accuracy & Rangeability — ±1.5 % FS standard (±1.0 % optional, gases remain 1.5 %); 10:1 turndown standard, up to 20:1 optional.

- High Pressure Rating — DN15–DN50: 4.0 MPa standard (32 MPa optional); DN80–DN200: 1.6 MPa standard (16 MPa optional).

- Extreme Temperature Capability — -80 °C to +450 °C (standard -20 °C to +120 °C; PTFE-lined 0–80 °C; jacketed/high-temp versions to 450 °C).

- Versatile Process Connections — Flanged (ANSI, DIN, JIS), threaded, clamp, or sanitary tri-clamp.

- Multiple Signal & Power Options — Local pointer, 24 VDC 4–20 mA (2/4-wire), HART protocol, battery-powered (3.6 V lithium), limit alarms, pulse output.

- Rugged Environmental Protection — IP65 housing; local indicator ambient -40 °C to +100 °C; remote transmitter to +85 °C.

- Low Maintenance Design — Only the float contacts the fluid; ideal for dirty, corrosive, viscous, or opaque media.

Specification

| Porduct | Metal Tube Rotameter |

| Model | SUP-LZ |

| Range | Water (20℃) (01~200000) L/h Air (20,0.1013MPa) (0.03~3000) m³/h |

| Range ratio | Standard 10:1 Optional 20:1 |

| Accuracy | Standard: 1.5% Optional:1% Gas: 1.5% |

| Pressure | standard:DN15~DN50≤4.0MPa DN80~DN200≤1.6MPa Optioanl: DN15~DN50≤32MPa DN80~DN200≤16MPa |

| Connection | Flange, Clamp, Thread, Sanity thread |

| Medium temperature | Standard:-20℃~120℃ PTFE 0℃~80℃ High temp:120℃~450℃ low temp: -80℃~-20℃ |

| Environment temperature | Remote type: -40℃~85℃ Pointer type/local alarm type -40℃~100℃ |

| Power supply | Standard type: 24VDC two-wire system (4-20) mA (12VDC~32VDC) Alarm type: 24VDC multi-wire system (4-20) mA (12VDC~32VDC) AC type: (100~240) VAC 50Hz~60Hz Battery type: 3.6V@9AH lithium battery |

| Load resistance | RLmax: 600Ω |

| Alarm Output | Upper and lower limit instantaneous flow alarm. Local alarm type: upper limit, lower limit, or upper and lower limit instantaneous flow alarm (Contact capacity 1A@30VDC). Upper limit and lower limit alarm hold range is a maximum of 60% the range, and the minimum interval between upper and lower limit alarms are 10% of the range |

| Pulse output | Cumulative pulse output is the output of the optocoupler signal isolation Darlington tube (internal 24VDC power supply, maximum current 8mA) |

| Ingress protection | IP6 |

Applications

The SUP-LZ liquid rotameter is trusted worldwide wherever operating conditions exceed the limits of glass rotameters:

- Chemical & petrochemical plants: Precise dosing and monitoring of acids, alkalis, solvents, and high-pressure reagents.

- Oil & gas and refining: Reliable measurement of crude oil, refined products, LPG, and viscous hydrocarbons.

- Water & wastewater treatment: Flow control in chemical injection, filtration, distribution, and sludge lines.

- Food & beverage production: Hygienic tri-clamp models for dairy, juices, beer, syrups, and CIP/SIP processes.

- Pharmaceutical & biotechnology: Sterile monitoring of purified water, solvents, and critical process liquids.

- Power generation & utilities: Cooling water, boiler feedwater, fuel oil, steam condensate, and compressed air systems.

- General heavy industry: Any high-temperature, high-pressure, corrosive, or opaque fluid application requiring long-term accuracy and minimal downtime.