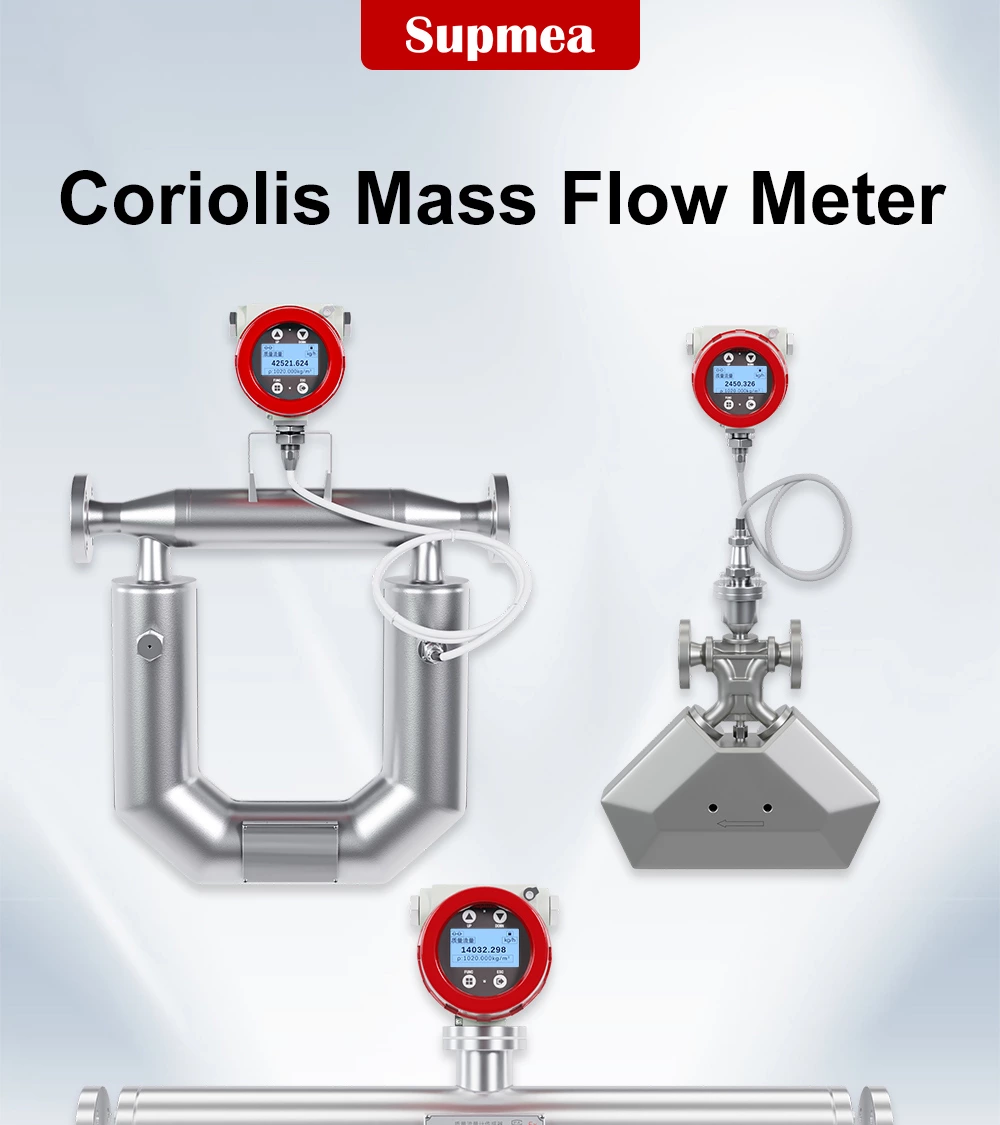

Coriolis Effect Mass Flow Meter: High Accuracy Measurement for Industrial Fluids

Coriolis Effect Mass Flow Meter: High Accuracy Measurement for Industrial Fluids Detail:

Introduction

SUP-Coriolis effect mass flow meters are advanced instruments designed for precise mass flow measurement in pipelines, relying on the Coriolis effect to deliver accurate results for liquids, gases, and slurries. Unlike traditional volumetric meters, they directly assess mass flow, density, and temperature, making them independent of fluid properties like viscosity or pressure changes. These meters feature vibrating tubes that detect subtle deflections caused by flowing media, offering high reliability with minimal maintenance. Commonly used in industrial settings, Coriolis flow meters support a broad range of flow rates and line sizes, ensuring consistent performance in demanding conditions. Their accuracy makes them a go-to choice for processes requiring exact data.

Working Theory

The core working principle of a Coriolis flow meter stems from the Coriolis effect, a phenomenon where a moving mass in a rotating frame experiences an apparent force, leading to deflection. In the meter, this is applied through one or more tubes, often U-shaped or straight, that are vibrated at their natural resonant frequency using an electromagnetic drive system. When no fluid flows, the tubes oscillate in sync. As fluid enters and splits evenly through the tubes, it accelerates toward the peak vibration point and decelerates away from it, generating opposing Coriolis forces that cause the tubes to twist.

Sensors positioned at the inlet and outlet detect this twist as a phase shift or time delay (Delta-T) between the vibration signals. This phase shift is directly proportional to the mass flow rate, allowing for precise calculation without influence from external factors like temperature or density variations. Additionally, the resonant frequency of the tubes changes with the fluid’s density, enabling simultaneous density measurement; a lower frequency indicates a higher density. Volume flow can then be derived by dividing mass flow by density.

Integrated temperature sensors monitor the tube material’s thermal expansion, ensuring accuracy across conditions. The design minimizes moving parts, reducing wear and supporting multiphase flows. Overall, this multivariable approach provides comprehensive data, making Coriolis meters suitable for both low-flow precision and high-volume applications, with outputs available via digital protocols like HART or Modbus.

Specification

| Diameter | U-type:DN20~DN150; Triangular:DN3~DN15; Straight Tube:DN8~DN80 |

| Measurand | Mass flow, density, temperature |

| Density accuracy | Earth 0.002g/cm³ |

| Accuracy | 0.1%,0.15%,0.2% |

| Temperature | -40℃~+60℃ |

| Power consumption | <15W |

| Power supply | 220VAC ; 24VDC |

| Signal output | 4~20mA, RS485, HART |

| Ingress protection | IP67 |

| Density range | (0.3~3.000)g/cm³ |

| Repeatability | 1/2 of the measurement error |

| Medium temperature | Standard type: (-50~200)℃, (-20~200)℃; High temperature type: (-50~350)°C; Low-temperature type: (-200~200)°C |

| Process pressure | (0~4.0)MPa |

| Humidity | 35%~95% |

| Transmission output | (4~20) mA, output load (250~600) Ω |

Applications

Coriolis flow meters find use in oil and gas for custody transfer and pipeline monitoring, chemical processing for batching corrosive fluids, food and beverage for ingredient dosing, pharmaceuticals for accurate liquid handling, and water treatment for flow control. They excel in clean energy research like fuel cell testing, manufacturing for color dosing, and coating processes in batteries or solar panels. Their versatility supports high-pressure, low-flow, and multiphase applications across industries.

Product detail pictures:

Related Product Guide:

To create more benefit for buyers is our business philosophy; shopper growing is our working chase for Coriolis Effect Mass Flow Meter: High Accuracy Measurement for Industrial Fluids , The product will supply to all over the world, such as: Mecca, Marseille, Angola, We supply skilled service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound items with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ??customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.